Process Optimization

Nozzles

Delivering Focus and Repeatability

An integral part of any MicroBlasting system, the nozzle provides focus and acceleration to the abrasive stream generated by the blaster. A good nozzle is designed to resist wear. Comco nozzles are manufactured from high-grade tungsten carbide and feature threads that sit away from the abrasive stream. The superior quality of Comco nozzles guarantees the highest level of repeatability with every blast.

Looking for a part number? Click here.

What drives Nozzle Selection?

- Part Design: This incorporates the base material, size and intricacy of the part. For instance, a part with deep bores usually requires an extended nozzle.

- Process: Determine if the application requires deburring, texturing, stripping, cleaning, etching or milling. Nozzle distance is important, too. Some nozzles should be held close to a part to carve precise features, some should be held further back to give abrasive room to travel. If you want to cover a wide area, use a large nozzle. If you need to create precise features, use a small nozzle.

- Tank orifice size: The tank orifice should be 5x as large as the abrasive. The nozzle should be the same size or larger than the tank orifice.

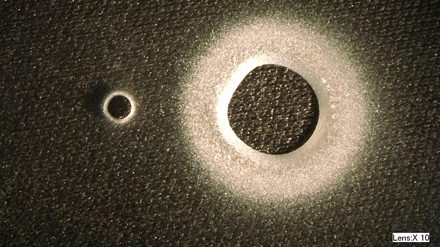

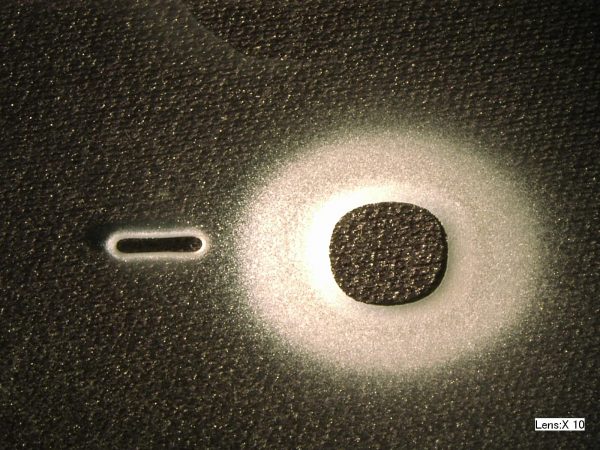

A Note About Rectangular Nozzles

Rectangular nozzles are not designed to sweep or fan abrasive over a part surface. More often than not, rectangular nozzles are not an efficient option as their design actually slows abrasive down. Rectangular nozzles are designed to make exact rectangular cuts. These nozzles should be held close to a part surface to get precise features. The spot size from a rectangular nozzle grows rounder and uneven as it is pulled away from a surface.

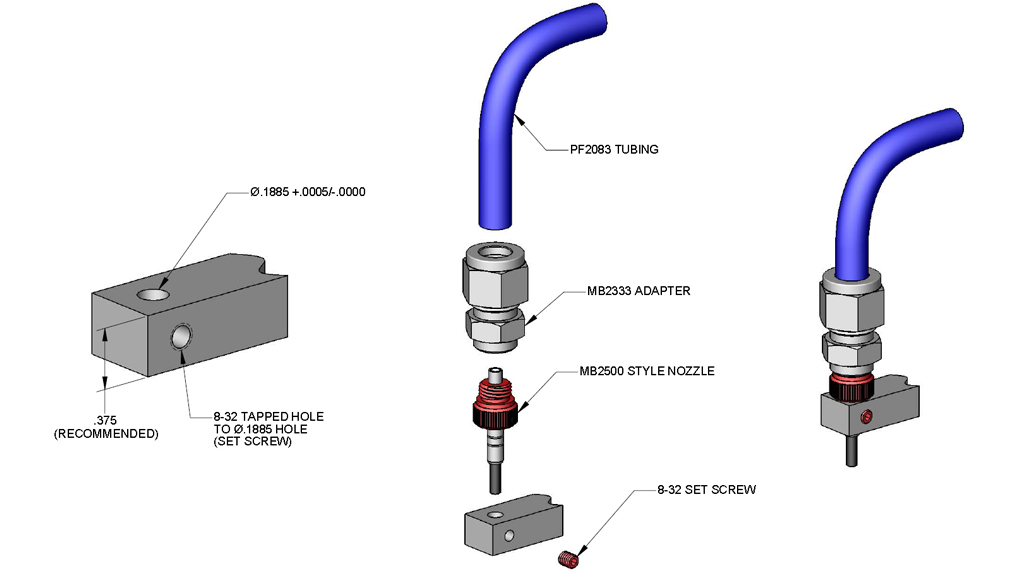

Easy Fixturing with AccuFlo Nozzles

Thinking about automation? Starting with Hi/Performance AccuFlo nozzles in your manual application will save time when you are ready to automate. The MB2520 Series nozzles are designed to smooth the transition as your production grows.

Quicknut Compatible

All AccuFlo nozzles are quicknut compatible, which means installation is quick! The gold quicknut need only be finger tight to lock the abrasive hose onto the back of the nozzle. There is no need for an additional nosepiece, handpiece, or o-ring.

Maintains Nozzle-to-Target Distance

The AccuFlo nozzle is designed to be held just above its carbide tip, which keeps nozzle-to-target distance consistent through hose and nozzle replacements.

Longer Life

The threads on an AccuFlo nozzle are designed to sit away from the abrasive path. Guarding this significant wear point from the abrasive stream dramatically extends the life of the nozzle.

Standard Nozzles Deliver Variety

Most applications benefit from the efficiency and precision of the Hi/Performance nozzle; however if only occasional blasting is required or if the application requires a different approach, reach for a Standard nozzle. Standard nozzles come in a variety of sizes, angles and lengths.

- Round nozzles, ideal for occasional blasting, feature openings ranging from 0.015″ to 0.046″.

- Rectangular nozzles make precise rectangular cuts.

- Angled and extended nozzles direct the abrasive stream into hard-to-reach areas of a part like deep bores.

- Conductive nozzles are designed for static-sensitive applications. These nozzles limit the potential for a static charge to build up and harm a circuit board.

All Comco nozzles are color-coded for easy identification.

Comfort at your fingertips

Long hours blasting need not be hard on your hands! Hi/Performance AccuFlo® nozzles come with the bonus of a well-designed holder. Our ComfortGrip® Handpiece eliminates the need for a nosepiece and locks directly to the nozzle. Plus, it is more comfortable to hold and maneuver for long periods of time.

What makes the ComfortGrip® Handpiece such an asset?

- Patented design provides the ultimate in comfort and performance.

- New ergonomic shape and cushioned grip for a natural feel that’s easier for operators to hold.

- Less resistance to motion for enhanced control and reduced fatigue.

- Fewer parts of this design come into contact with abrasive, which means fewer parts to replace.

- Compatible with most popular nozzle sizes: .018″, .030″, .046″, .060″ ID.

Ready to upgrade from the MicroBlaster handpiece? The ComfortGrip Handpiece is compatible with any of the MicroBlaster units.

Nozzle Alignment Laser

The Nozzle Alignment Laser makes fixturing applications easier. This add-on attaches at the nozzle and defines the abrasive target area before blasting.

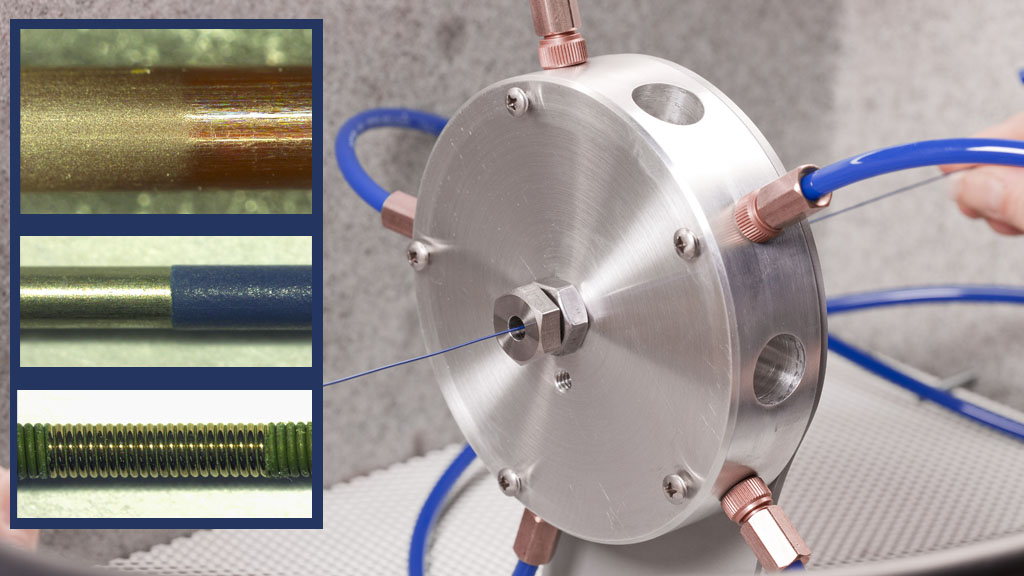

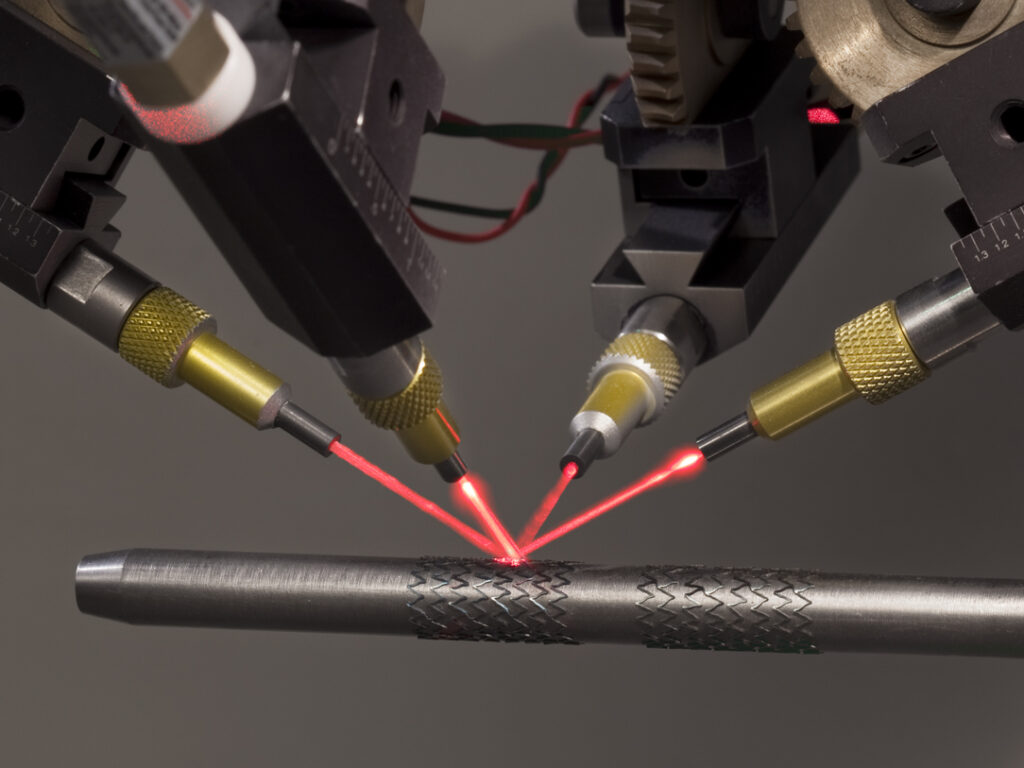

Ring Nozzle

The Ring Nozzle is a 5-nozzle attachment that focuses multiple streams of abrasive onto a single section of a wire, rod or tube. Designed to provide 360° of uniform coverage.