Case Studies

Artifact restoration with MicroBlasting

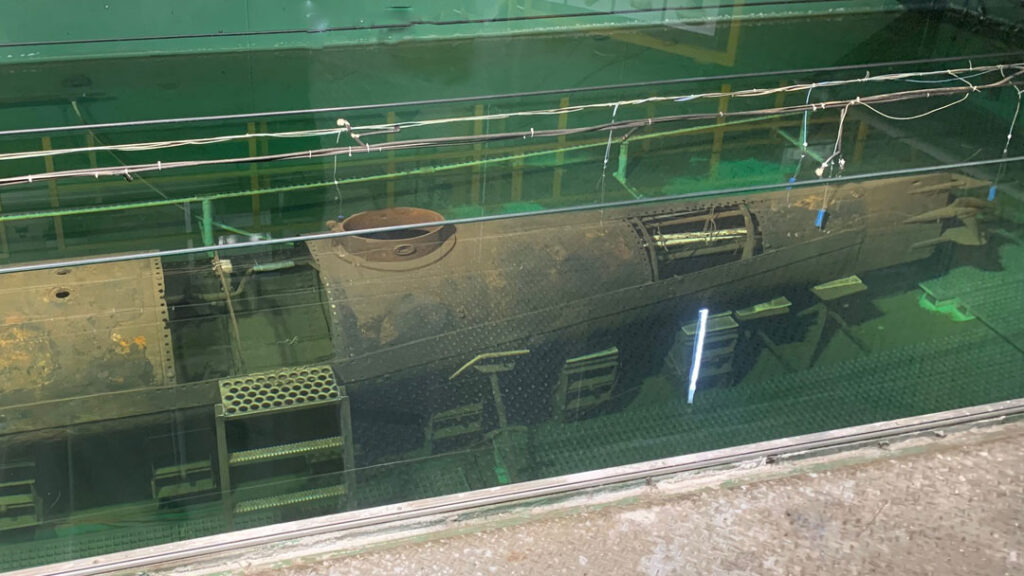

Bringing the Hunley Up to the Surface

The H.L. Hunley was a state-of-the-art submarine and warship that saw battle in the American Civil War. It is known for being the first submarine to sink an enemy vessel. It sparked our curiosity and a sense of wonder, which is why I was really excited to visit our customer at The Hunley Project.

The Hunley sank in Charleston harbor, South Carolina in 1864 following its successful mission. It was raised in 2000 and has been undergoing archaeological research and conservation treatment at the Warren Lasch Conservation Center in North Charleston ever since. The Center uses Comco MicroBlasting technology in their restoration work.

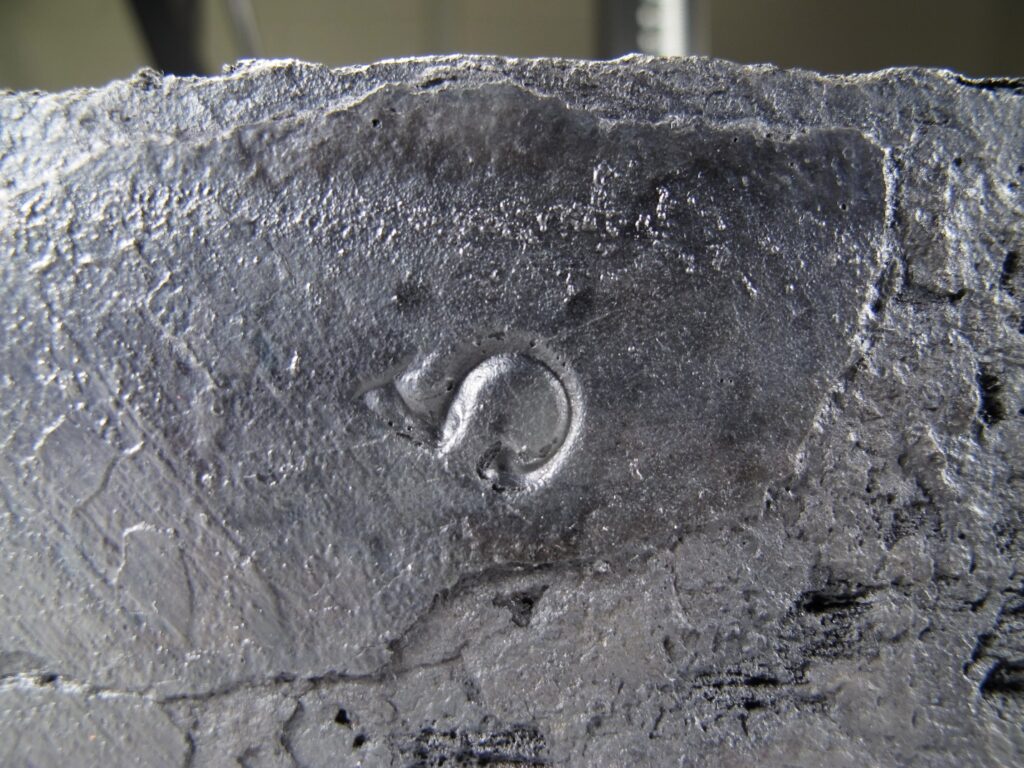

Restoring the Snorkel Box

The snorkel box was mounted on top of the H.L. Hunley submarine and was part of an air circulation system that was intended to bring oxygen into the vessel while it was submerged. The system included snorkel tubes that could be raised to the surface and bellows that could be operated from inside the submarine. The view seen here shows the interior of the snorkel box from underneath. Following desalination and drying, the entire box including the two copper valves in the center were microblasted with sodium bicarbonate using Comco equipment.

why Use MicroBlasting For this Delicate Work?

MicroBlasting provides just the right amount of precision and abrasion needed to remove the final layer of material around a delicate piece of history.

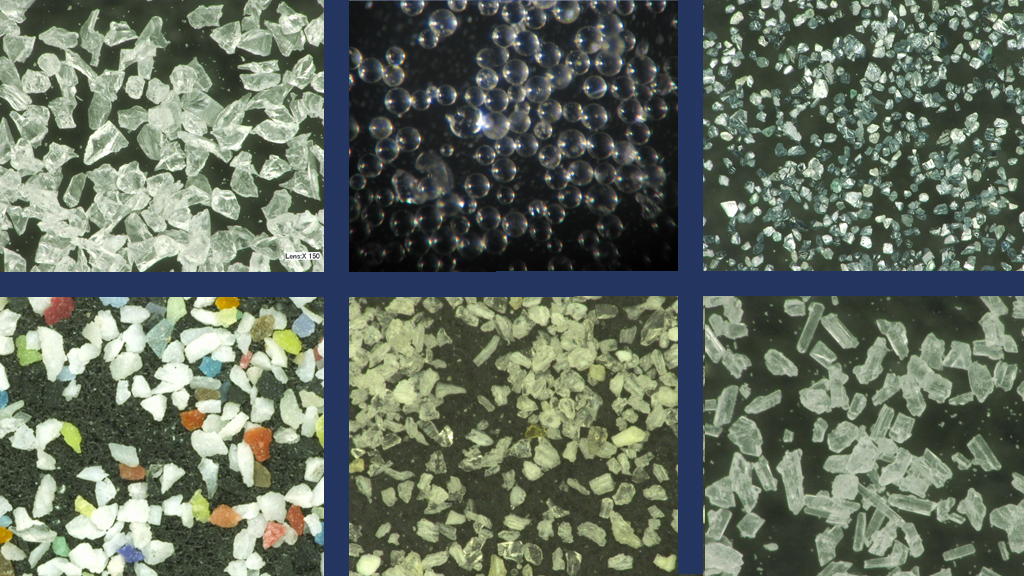

This technology affords the preparators the flexibility needed to dial-in their process and select the best abrasive, blast pressure, and nozzle size to remove each specific layer with the utmost precision. Sodium bicarbonate and pumice are often the go-to abrasives for artifact restoration. Both abrasives can gently chip away at debris without damaging the artifact underneath..

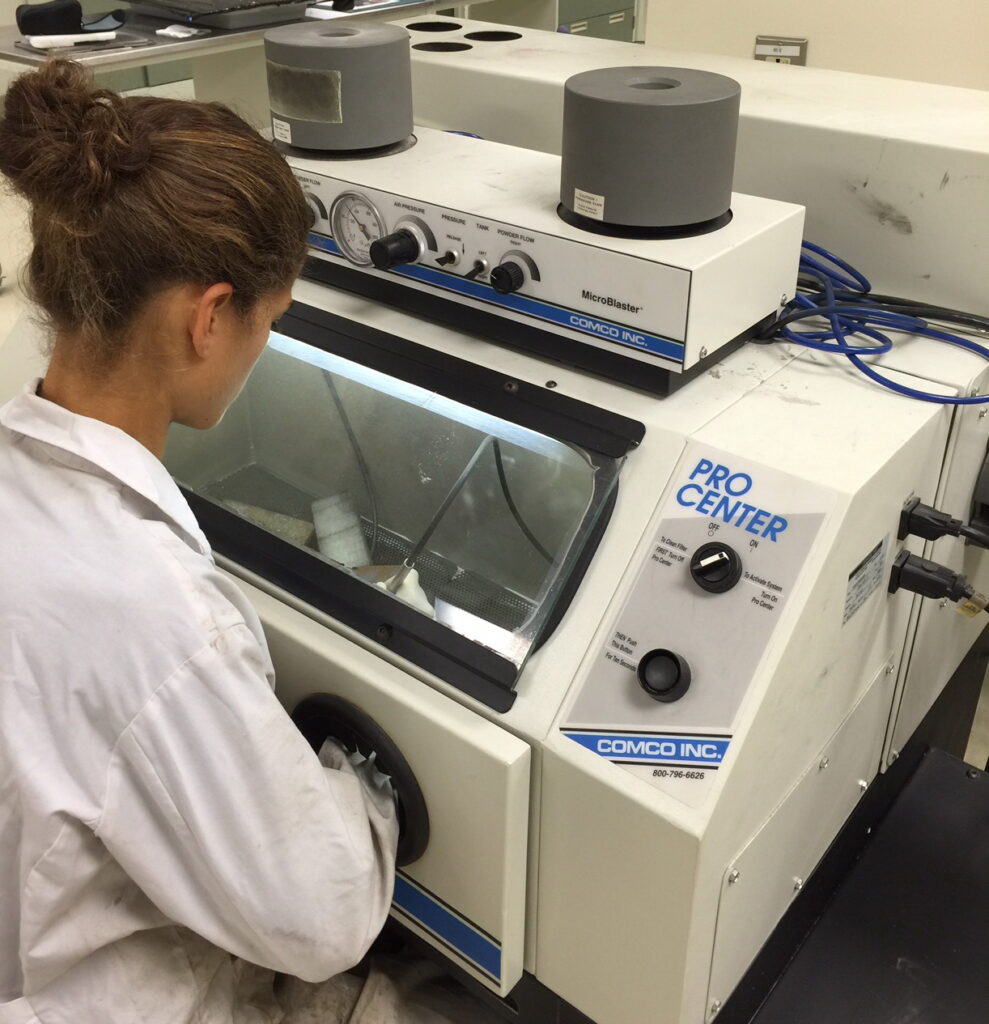

Equipment

The Dual Tank MicroBlaster is great for restoration work like this since the operator can flip easily between media when material removal demands a new approach. The workstation showcased below is our old ProCenter, but we custom-designed workstations to suit the size of larger specimens