03.04.2024

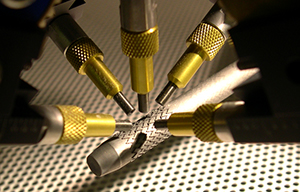

Stent Surface Engineering

01.17.2024

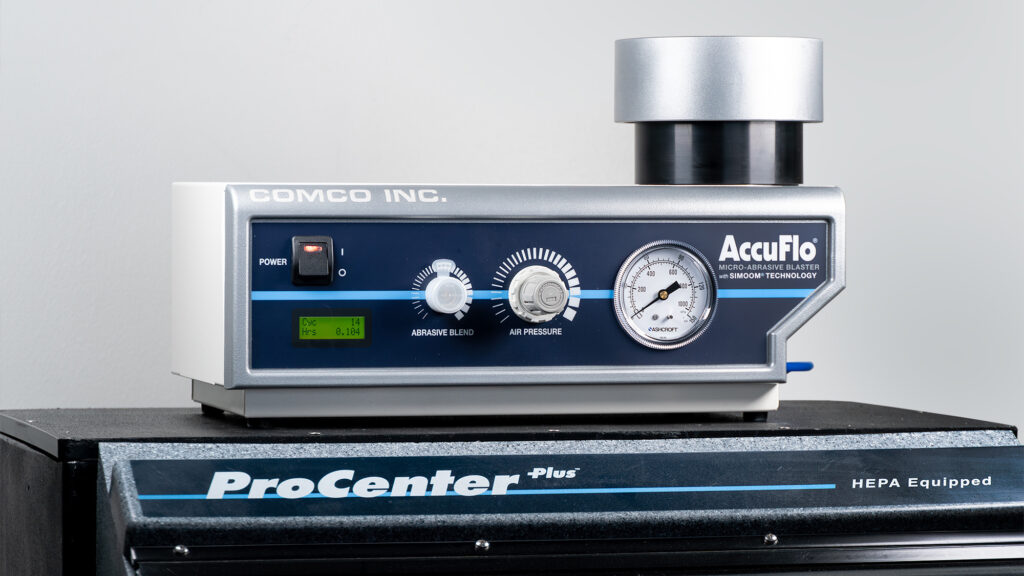

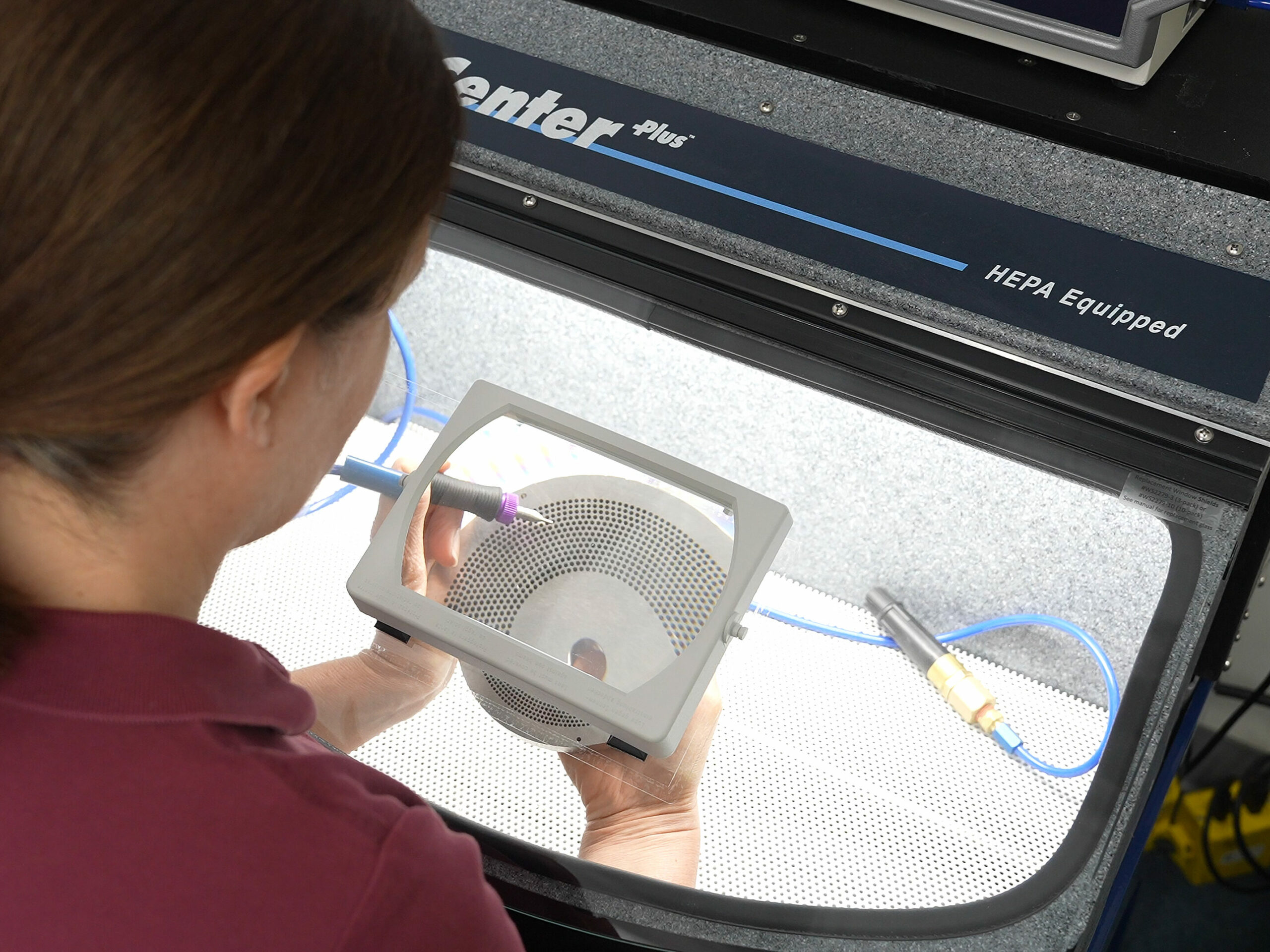

AccuFlo Upgrade: The Calibration Cap

01.10.2024

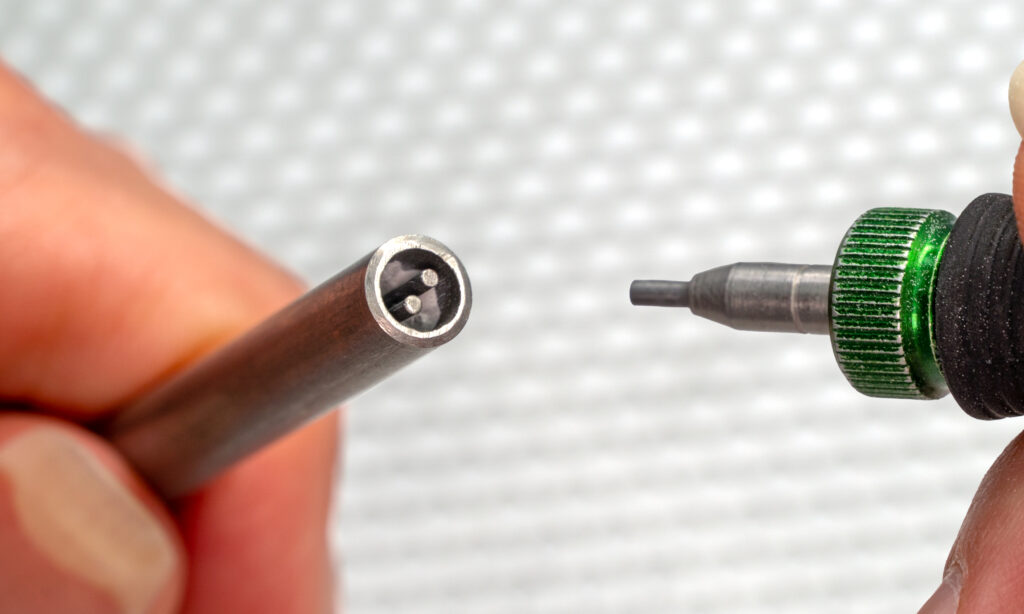

Thermocouples

01.10.2024

Understanding Modulator Wear and Repair

01.10.2024

Manuals

01.10.2024

Safety Data Sheets

01.09.2024

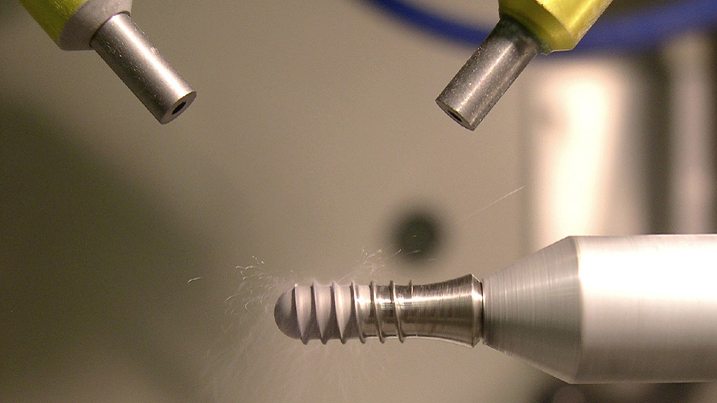

Dental Implants

01.09.2024

FAQ ProCenter Plus

12.20.2023