Case Studies

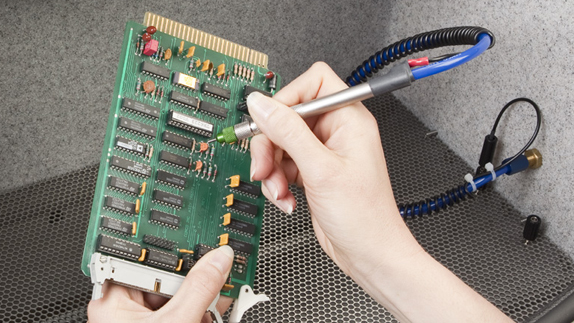

Decapping Integrated Circuits

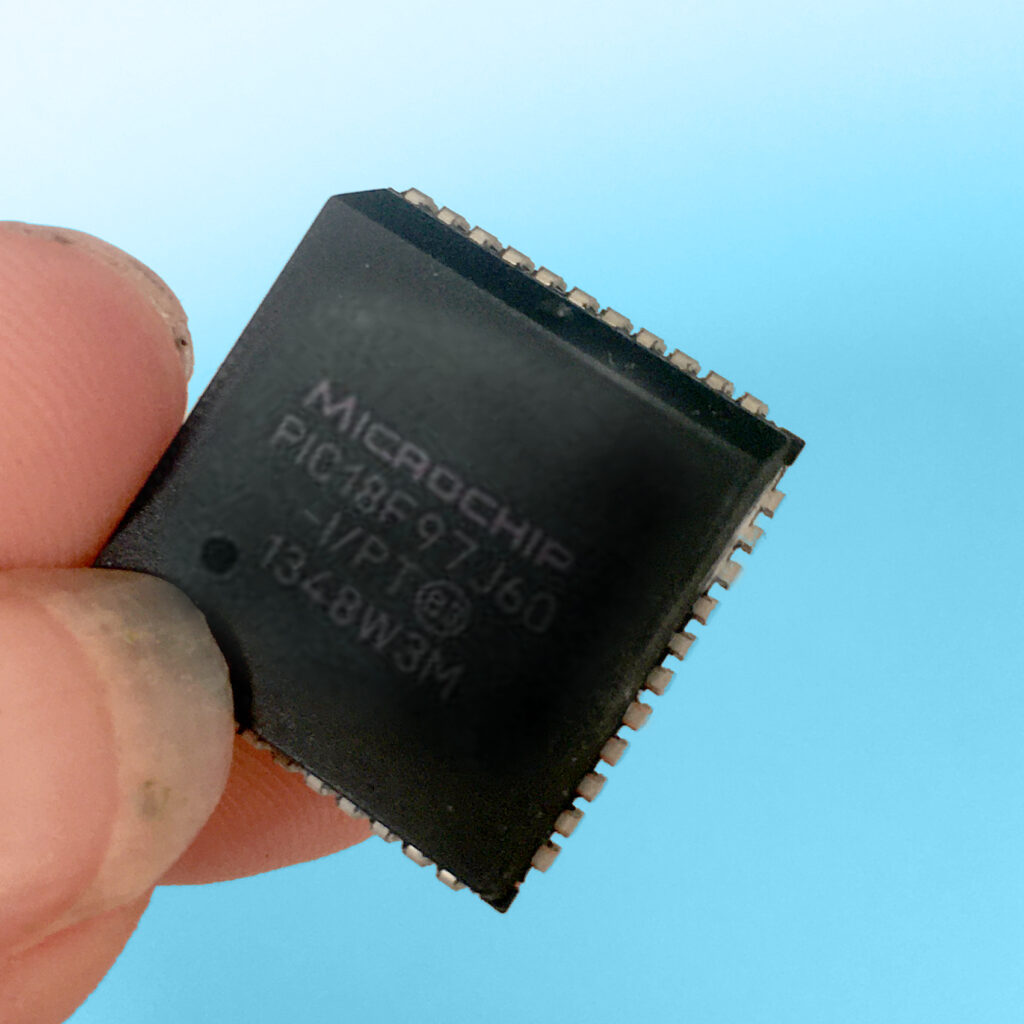

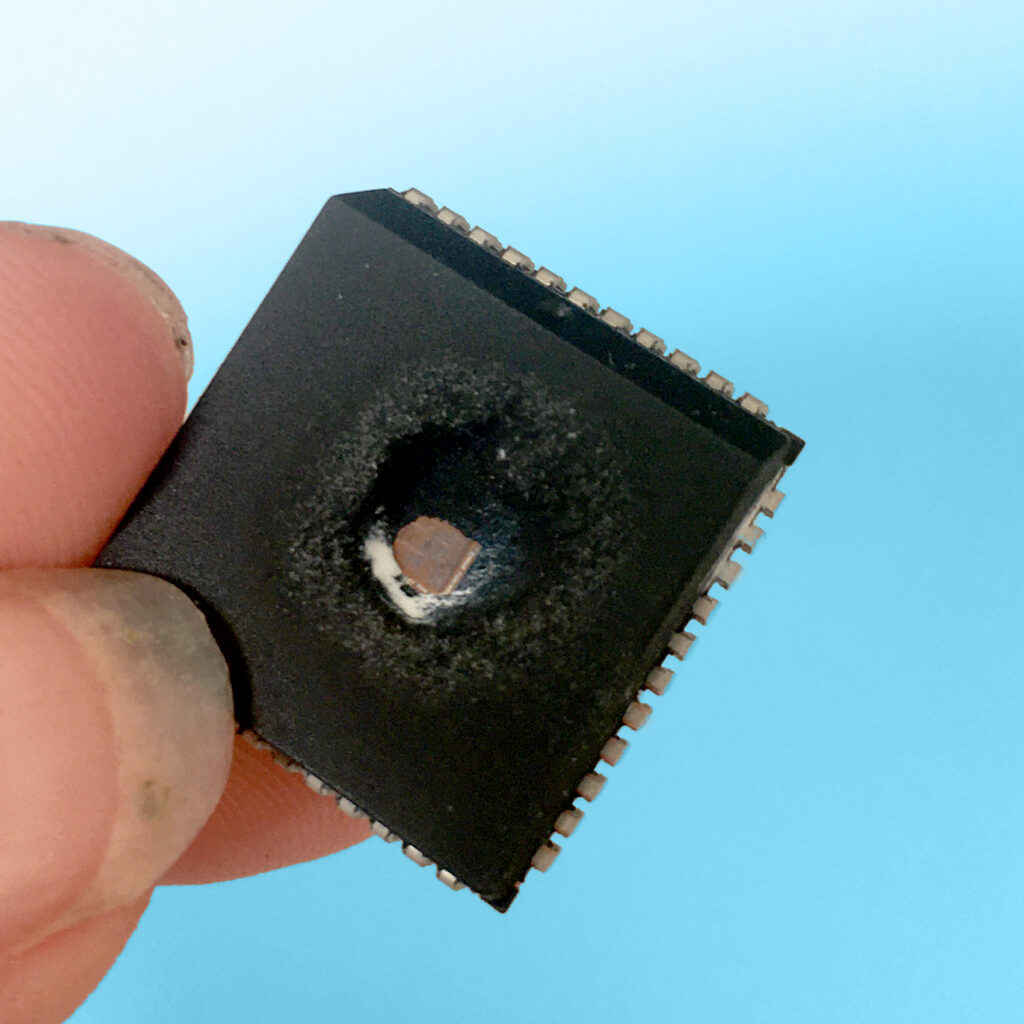

Delicate silicon dies are encapsulated in epoxy to protect them. This becomes a problem when extracting the silicon die for failure analysis or reverse engineering. When using MicroBlasting, decapping an integrated circuit is safer, easier and more environmentally friendly than other methods.

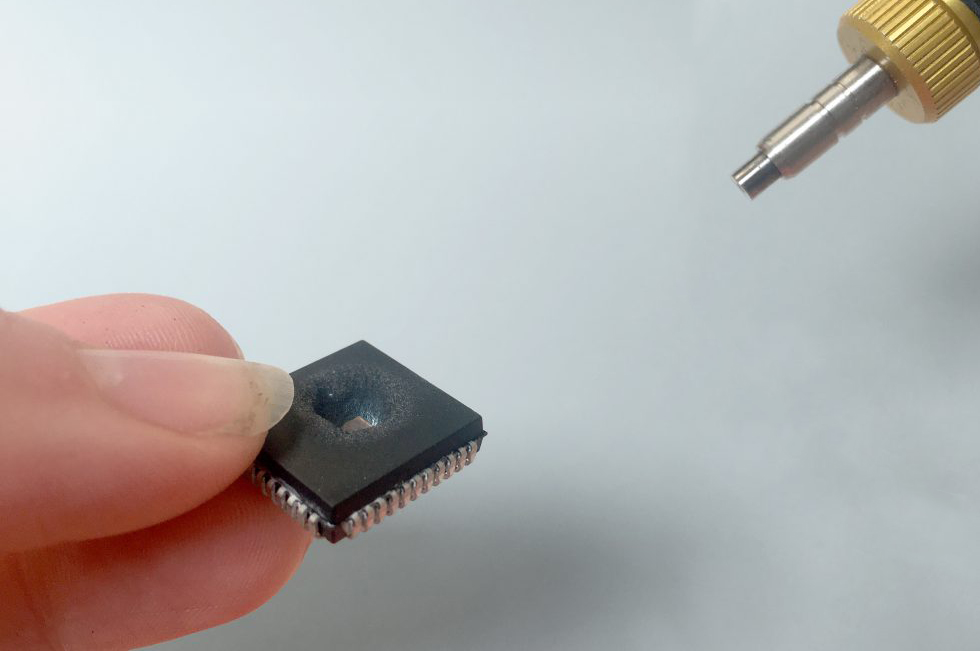

Fine abrasive particles moving at high velocities with a precision nozzle keep the area of removal small. Sodium bicarbonate works well for applications with two layers of different material (like this one) because it’s aggressive against ductile epoxy, but won’t damage harder ceramic. This reduces the risk of cutting the silicon die.

Parameters

- Abrasive: 50μ Sodium Bicarbonate

- Pressure: 120 psi

- Nozzle: 0.046″ Hi/Performance

Static Protection

Dry air and abrasive might seem like a hazardous environment for semiconductor devices. This isn’t the case. Our ESD Control ProCenter Plus™ eliminates the potential for static arcing on sensitive components.

Level Up Your Process

Don’t be afraid to try and automate a static sensitive application. Our JetCenter can incorporate the same ESD protection devices as our ProCenter Plus™.

If you have other unique concerns for your application, contact us! Each automated system is built for your specific application. Read more about the solutions our engineers have found for challenging applications.