Applications

Finishing 3D Printed Parts with MicroBlasting

Yes, we know that because it’s new and buzzy, every company worldwide wants to promise you that their product is a perfect tool for finishing 3D printed parts (or other processes related to additive manufacturing). We’ll be honest with you – MicroBlasting isn’t the answer for every application. However, in applications where MicroBlasting can be used, it’s the perfect companion to additive manufacturing.

The Final Step in Additive Manufacturing

An advantage of additive manufacturing is that it produces a part to exact specifications. For it to be completely finished however, a few additional steps are needed once it’s been removed from the printer. The applications we work with broadly fall into three buckets: smoothing out the “lines” on 3D printed parts, removing small bumps (called “caviar”) on titanium and cleaning out residue on internal surfaces of polymer printed components.

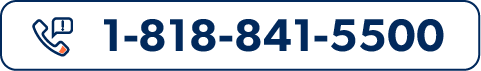

Smoothing out lines

For smoothing or reducing lines, glass beads are the perfect media. The spherical shape of glass beads keeps from cutting into surfaces. It “pounds” the part’s surface into a smooth, satin finish. On this part, we used 50 µm glass bead at 50 psi.

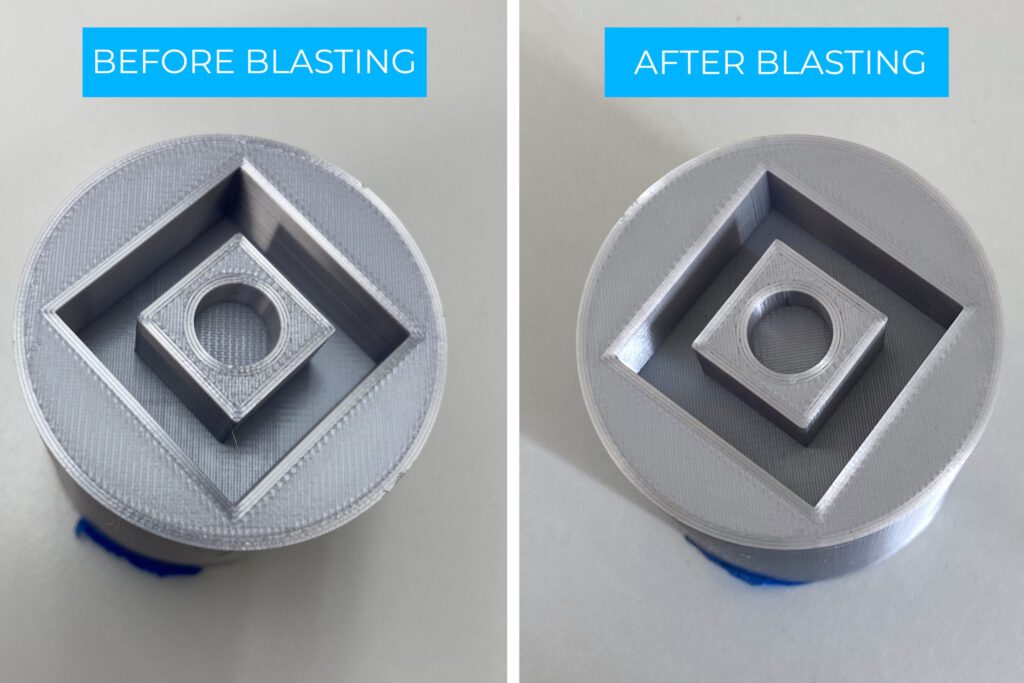

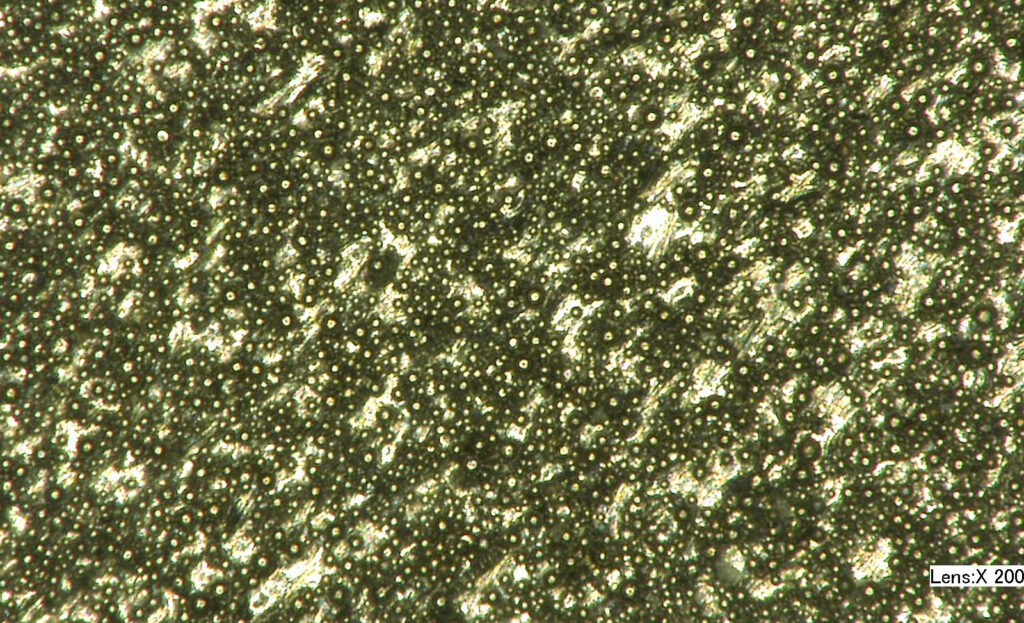

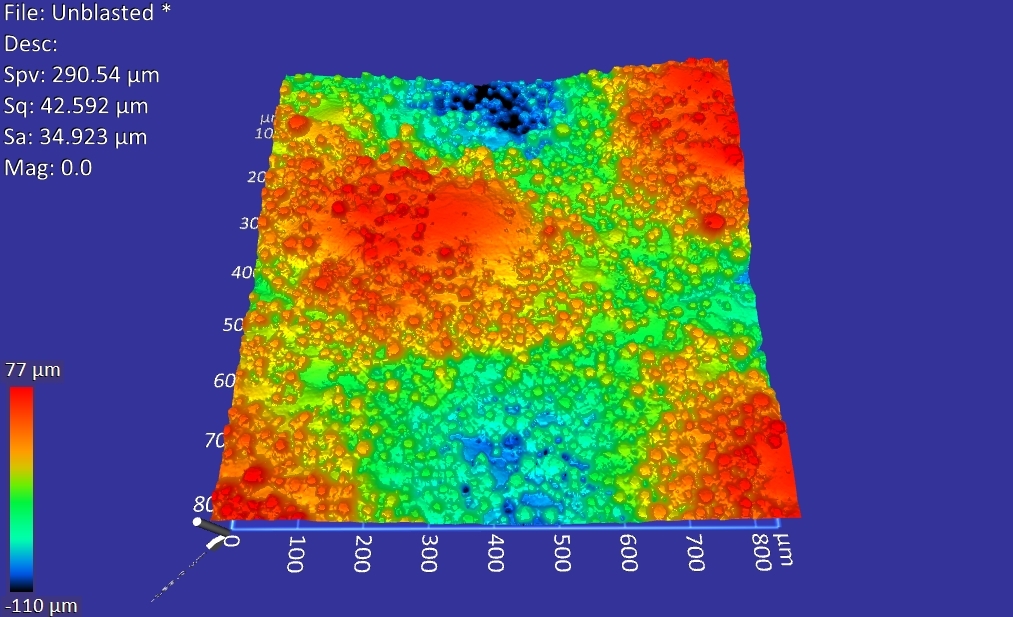

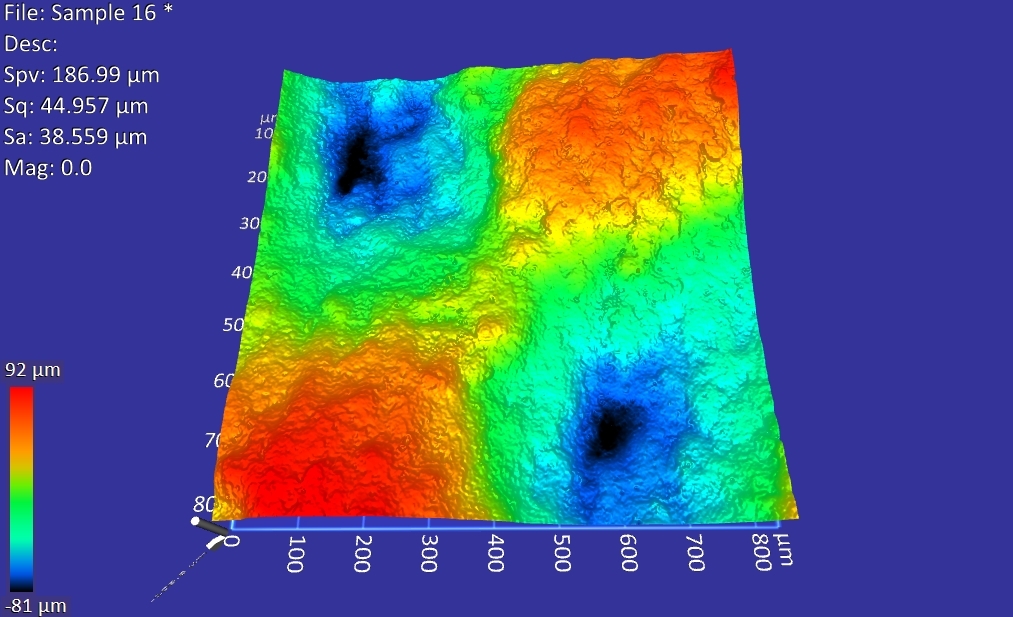

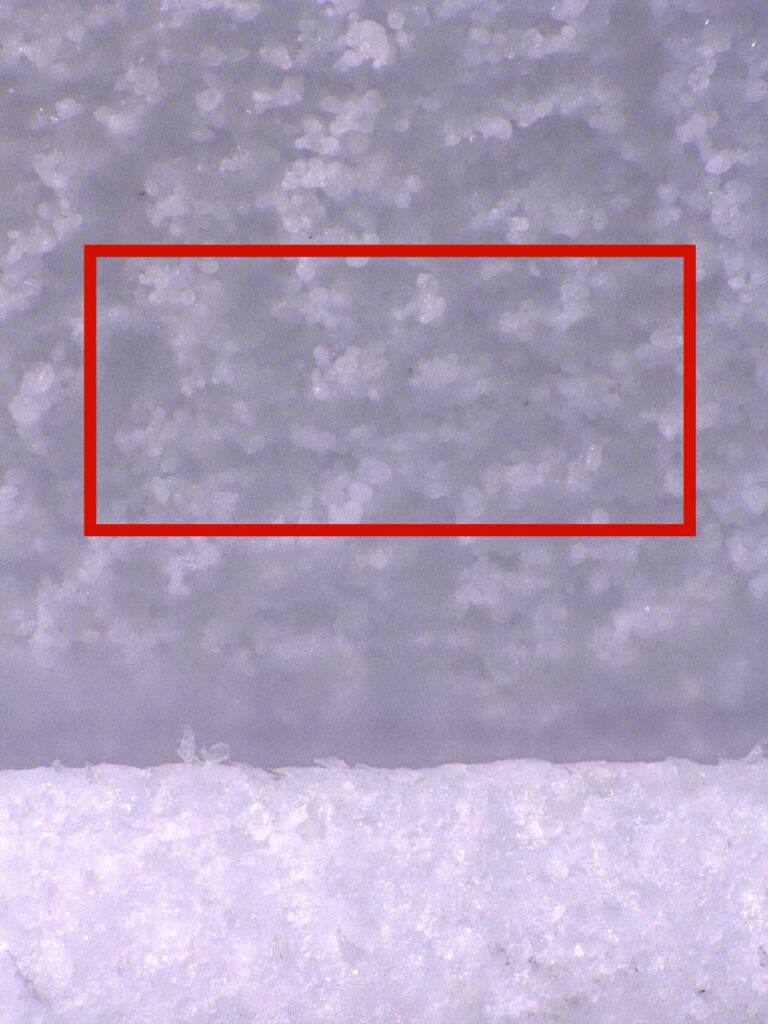

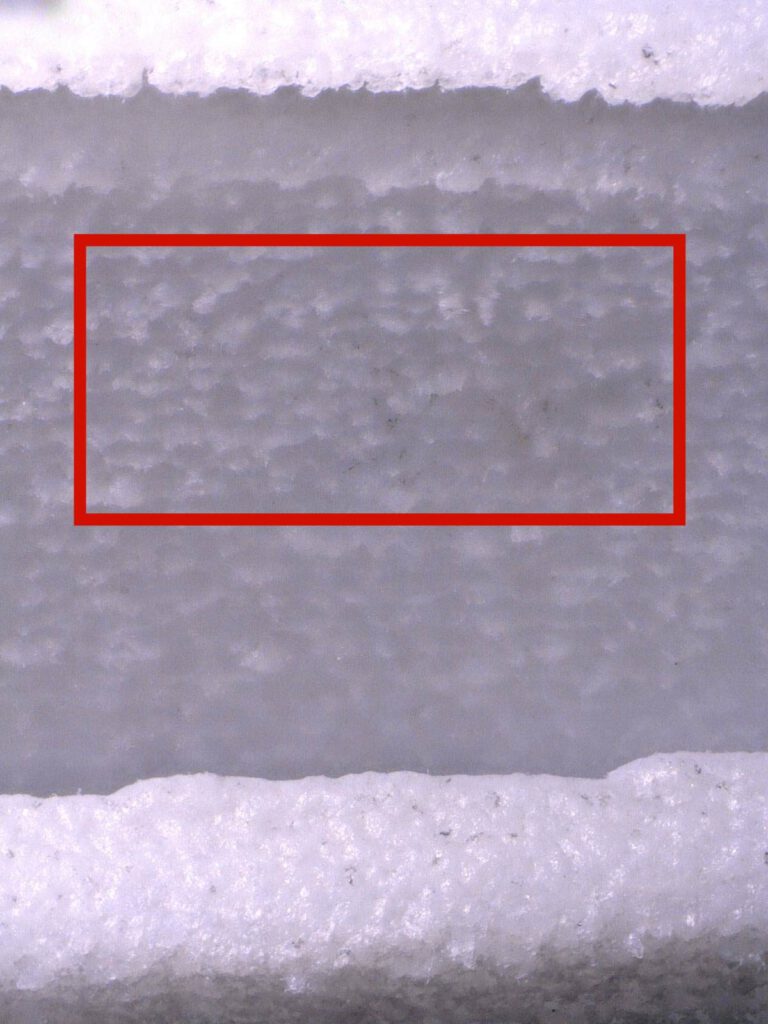

Removing bumps from 3D printed parts

The most common process used for additive manufacturing of titanium is laser sintering. This process is effective at merging individual layers of titanium into a cohesive whole. But, the outer layer can be negatively impacted by partially sintered titanium. The appearance of this material shows up as bumps, or “caviar”, on the surface. The best abrasive to remove caviar bumps is pumice, but aluminum oxide can work as well. In addition to removing the surface defects, these abrasives will leave a matte finish on the surface.

Removing polymer residue

A common byproduct of additive manufacturing for parts that have complex internal geometries is a residue that can build up on the surface. The internal geometries of the part prevent effective flushing of the additive material and during the layering process, it becomes semi-attached. The flushing action created by MicroBlasting (using glass bead) quickly scrapes this material off the surface of the part. The spherical nature of this abrasive prevents damage to the part itself.

Which system should I use to finish 3D printed parts?

The Manual System

When you have a low volume of parts to process or the location of lines and caviar are inconsistent, the Manual System is the best tool for finishing your 3D printed parts. Our manual system consists of our newest blaster, the AccuFlo, and our all in one workstation, the ProCenter Plus. With this system, you don’t need to purchase any additional equipment. It’s ready to go right out of the box!

Automated System

If you have a higher volume of consistent parts to process, our automated systems might be the best choice for you and your team. Our two automated platforms, the Advanced Lathe and JetCenter are customizable, flexible and easy to operate. Whether a manual or automated system is right for your 3D printing application, our team is ready to help you find the best option.