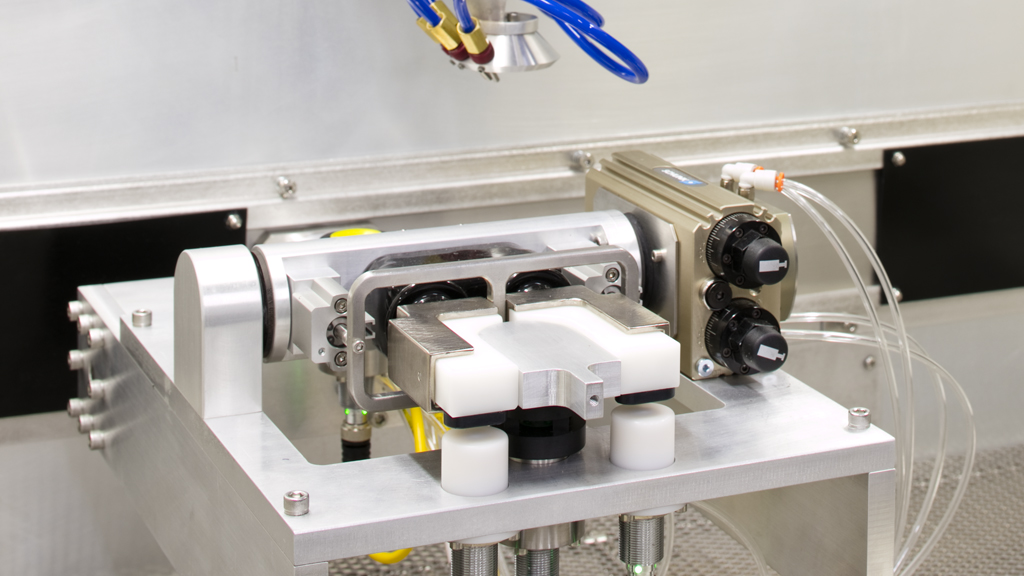

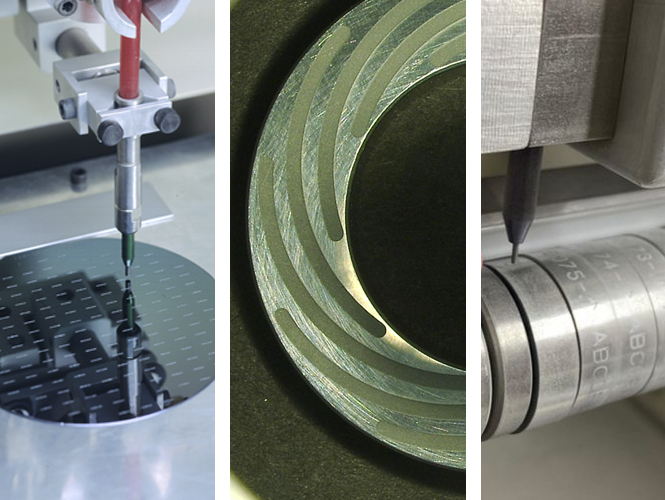

Equipment

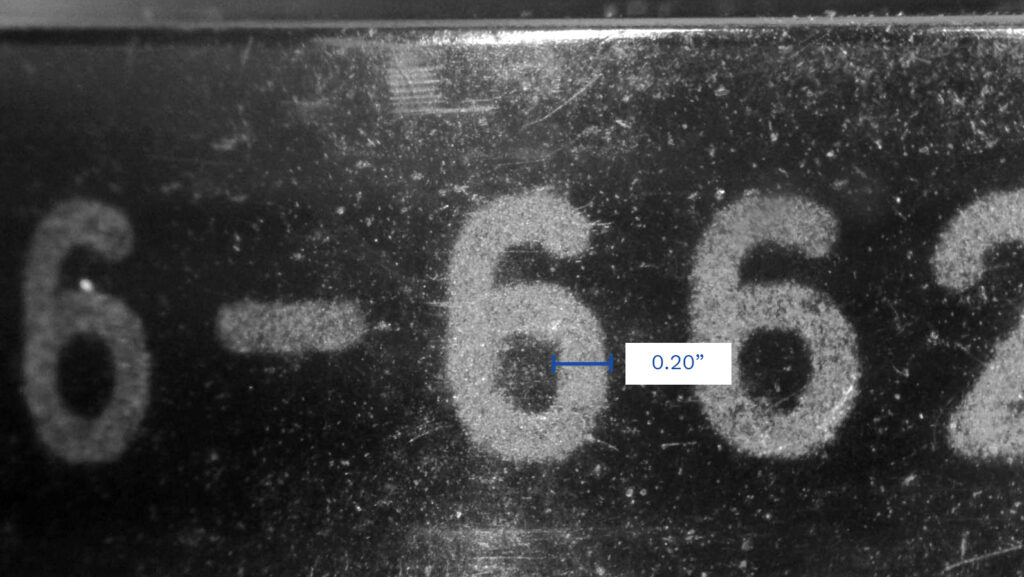

Lens Engraving with the Serializer

We’ve made a big update to one of our Automated Systems!

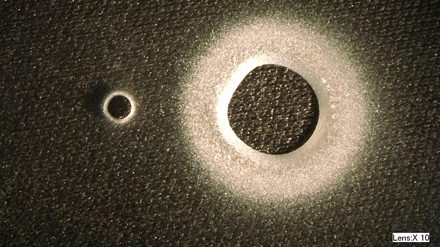

One of our favorite customization options is the serializer for our Advanced Lathe. This modification has long been used to engrave serial numbers on delicate ring laser gyro lenses without chipping or masking.

For our most recent serializers, our engineers have elevated the process by completely redesigning the PowderGate valve.

To see how they did it, and determine if your project could benefit from the serializer, check out the video below!

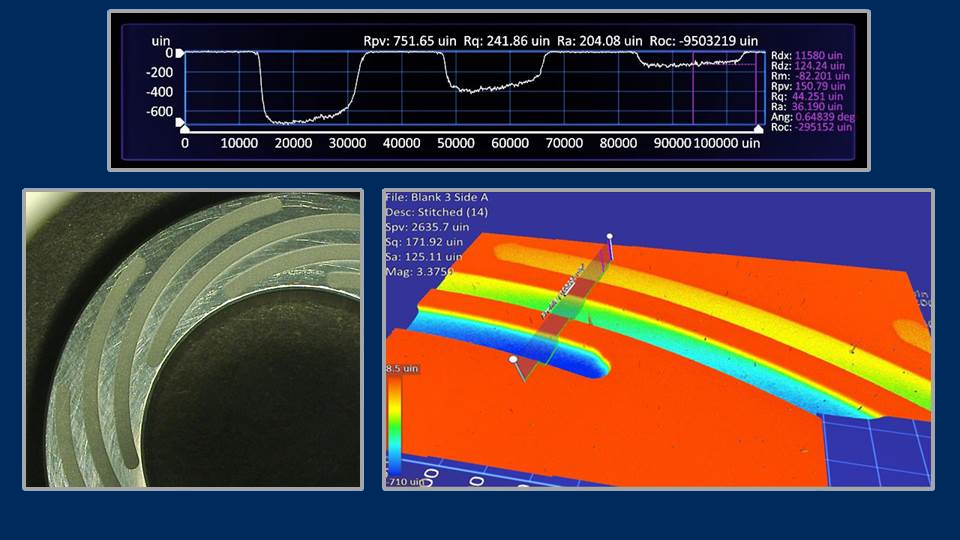

Blast Parameters and Results

Abrasive: 50µ aluminum oxide

Nozzle: 0.010″

Tank Orifice: 0.025″

Nozzle Distance: 0.04″