Maintenance & Troubleshooting

Oil Contamination: The preventative measures you need to take

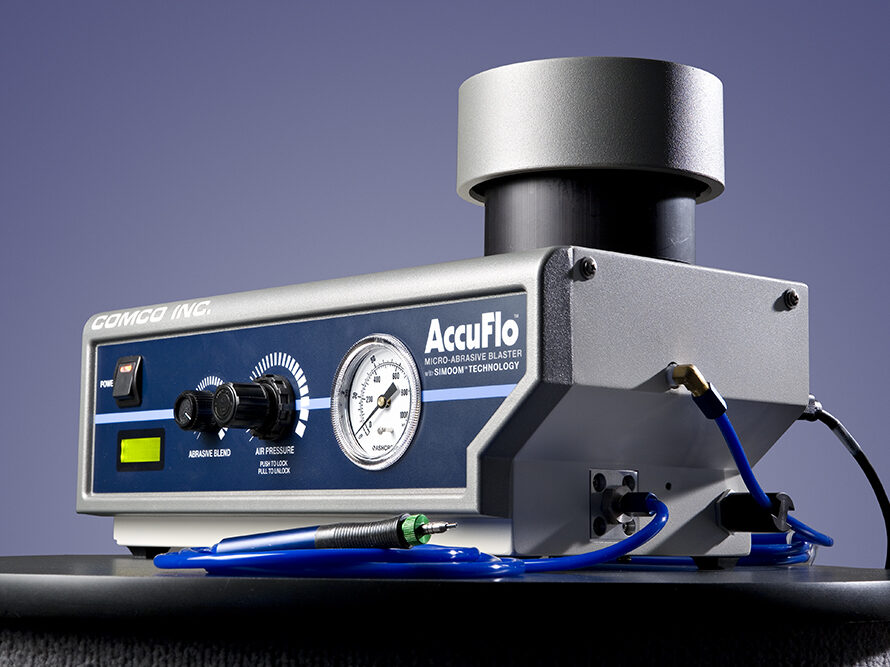

One of the major differences between micro-abrasive blasting and other types of sandblasting is the precision of the process. This is partly achieved by using very fine, tightly-classified abrasives. A clean, dry air supply must be provided to allow abrasive media to flow without interruption. If the air line becomes contaminated with moisture or oil, the effectiveness of the process will be severely limited. Even tiny amounts of oil contamination can cause major failures in the MicroBlasterʼs internal mechanisms.

Proper protection from oil is especially critical for micro-abrasive blasters that are connected to a shopʼs compressed air line. Often oil is added to air lines for pneumatic instrument lubrication, but this is damaging to a blaster. Older piston compressors tend to have leaky O-rings, putting oil into the air stream.

How to identify contamination

If you suspect that your MicroBlaster is contaminated with oil, there are a few signs you can look for to confirm this.

1. Watch the Air Line Color

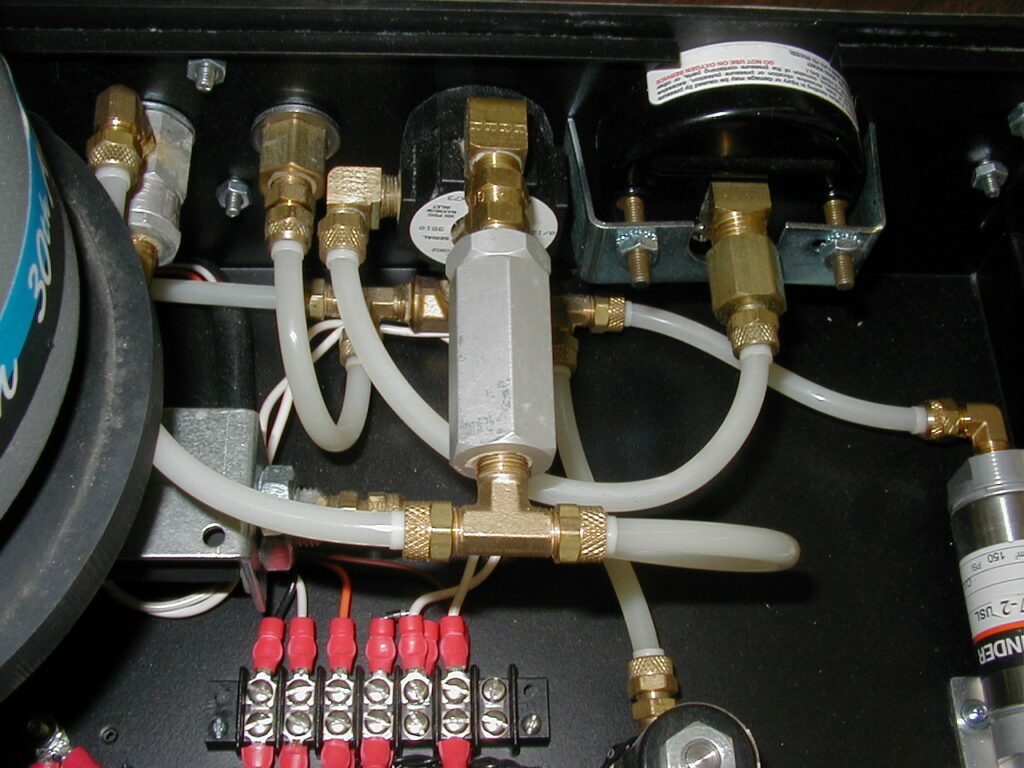

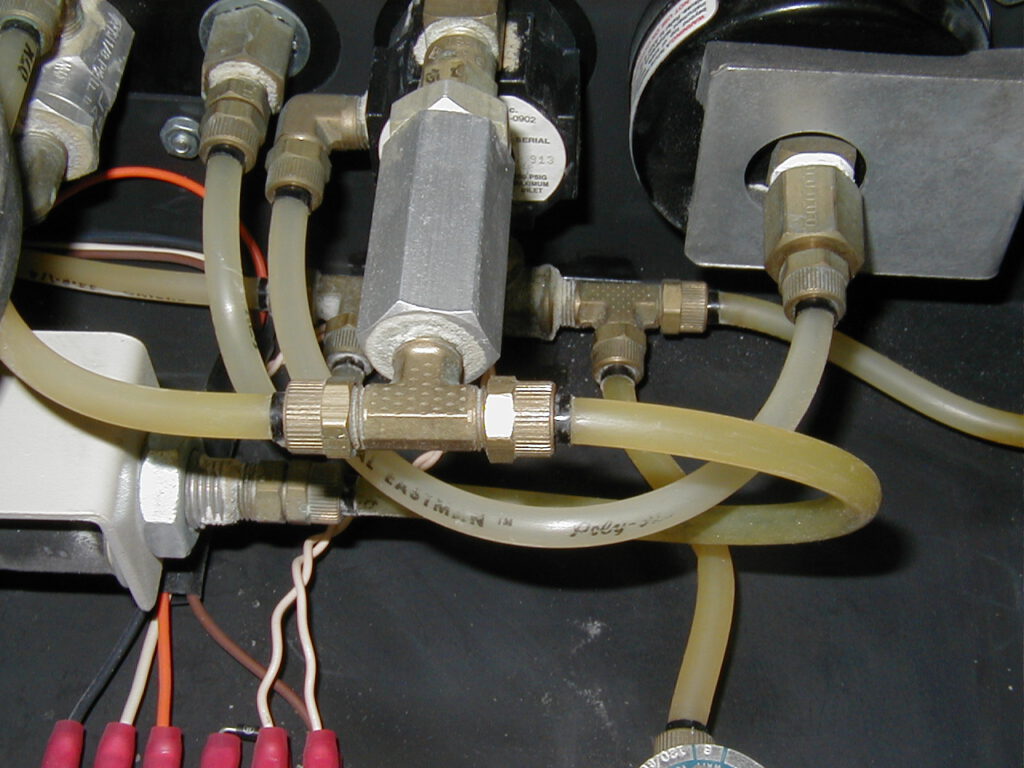

The air lines that run clean air through a Comco MicroBlaster are a milky-white color when new. Exposure to oil causes these air lines to turn orange or yellow color. Take a look at the air lines compared to the right.

2. Check for Oil Pools

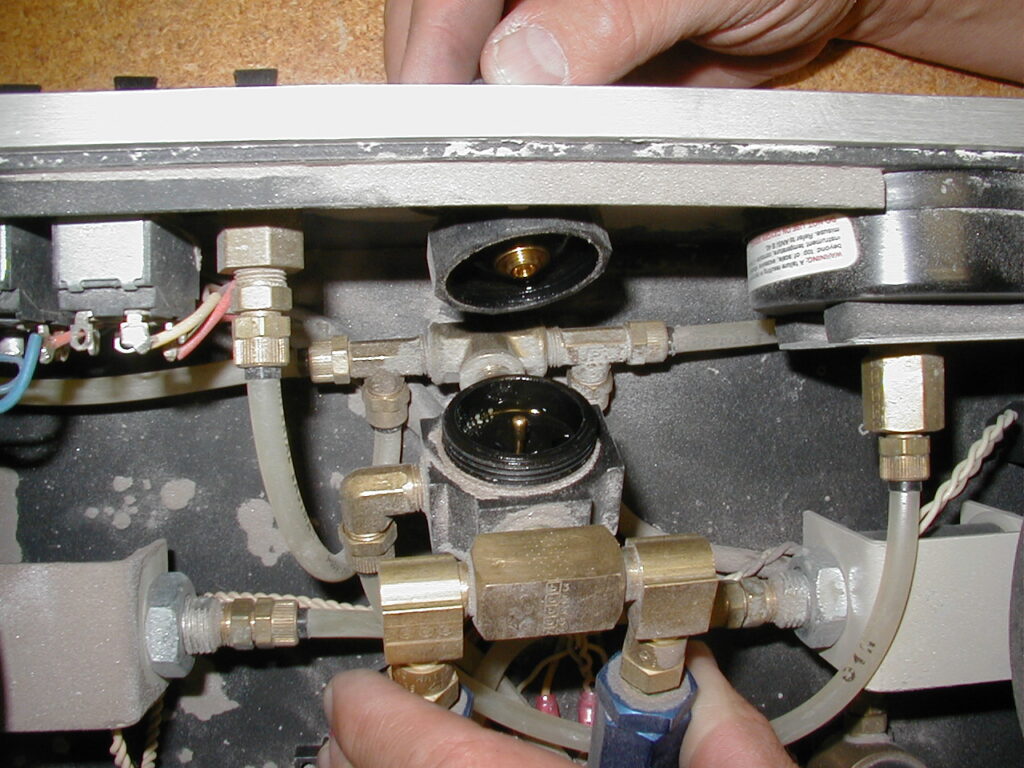

Oil has a tendency to pool in the regulator assembly of a Comco micro-abrasive blaster. Unscrew the black plastic bonnet to see traces of oil inside the regulator. Use the images below to compare against your own blaster interior. (Note: This can be a difficult area to access.)

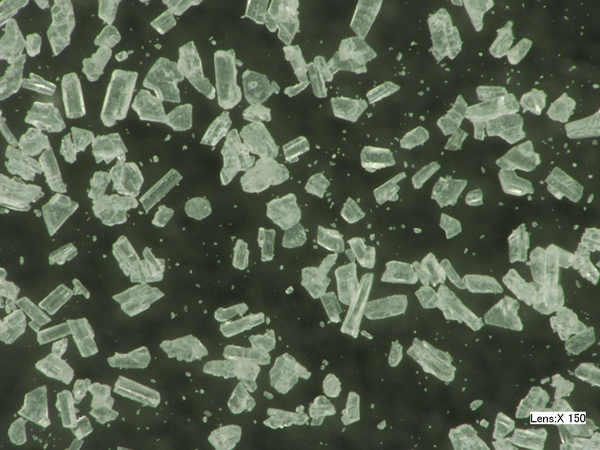

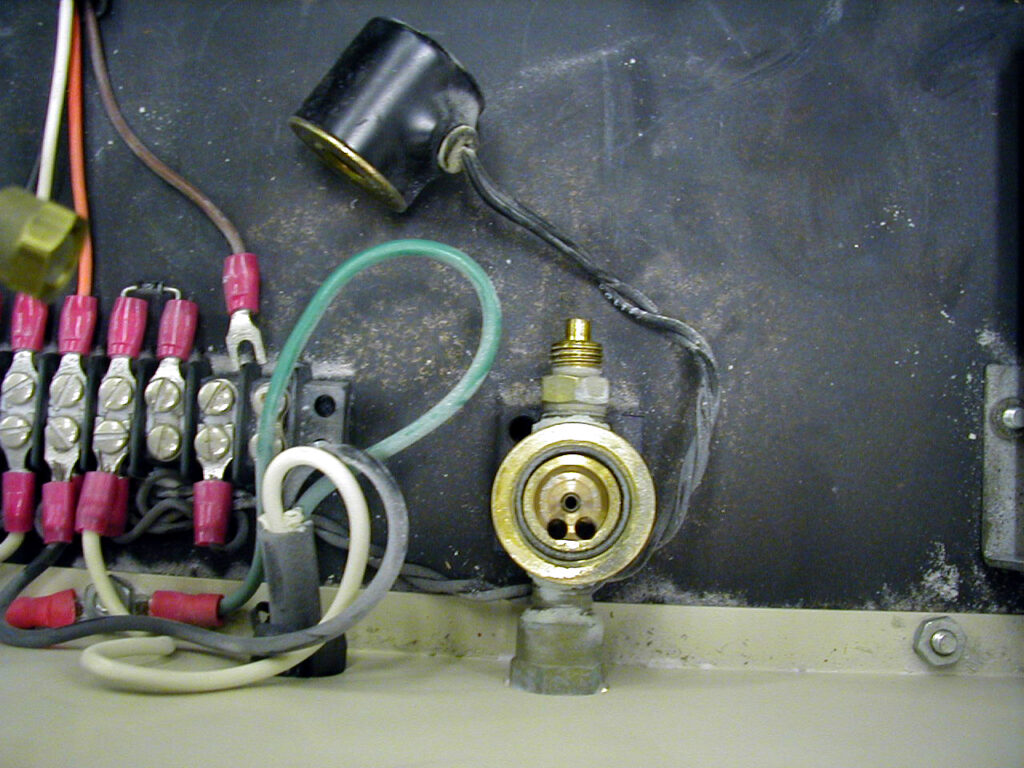

3. Look for Clumps

When oil contamination becomes severe, abrasive media adheres to the filter element. If you suspect severe oil contamination, open the assembly to expose the filter element and look for large clumps of abrasive. The image to the left show abrasive clumping due to oil contamination.

What can Oil Damage Do?

Initially, oil contamination in your micro-abrasive blaster causes irregularities in the abrasive flow. Abrasive clumps form above the abrasive tank orifice, limiting the amount of abrasive that can pass out to the abrasive hose and the nozzle. Sometime abrasive clumps pass through, only to form obstructions at the nozzle. These clumps can be identified by a mass of small particles that tend to break apart under force.

The major impact of oil contamination is check-valve failure. Oil contamination usually prevents the check-valve from sealing properly. When the check-valve fails to seal, air and abrasive particles pass back through the check-valve into the ‘clean’ side of the blaster’s system. Backward moving abrasive is detrimental to the proper operation of the valves and cylinders in this part of a blaster’s system. Abrasive is too aggressive and quickly erodes the O-rings and seals on these components. This type of damage to a blaster is quite costly to repair.

How to avoid Oil Contamination

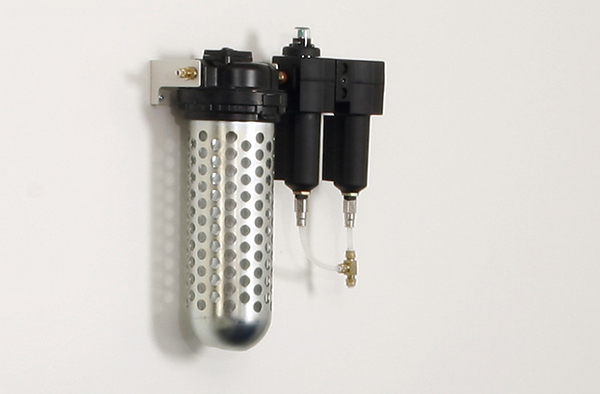

While oil contamination can cause a major disaster inside your blaster, it is one of the easiest problems to avoid. The compressed air line running to a Comco MicroBlaster should pass through an oil filter and air dryer just before it reaches the unit. Not only does the oil filter protect the blaster components, but it also keeps oil from coating the desiccant or membrane filter inside the air dryer, prolonging its useful life.