Process Optimization

How Far Should I hold the Nozzle from the Targeted Part?

We field this question daily. Here are the quick and dirty answers:

- For a sharp edge and a steep wall, hold the nozzle close, or 0.025”- 0.060” from the target.

- For greater coverage, hold the nozzle farther away, or 1″-3” from the target.

Now, if only all applications were that simple…

What is Spot Size?

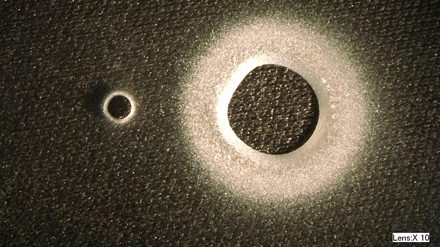

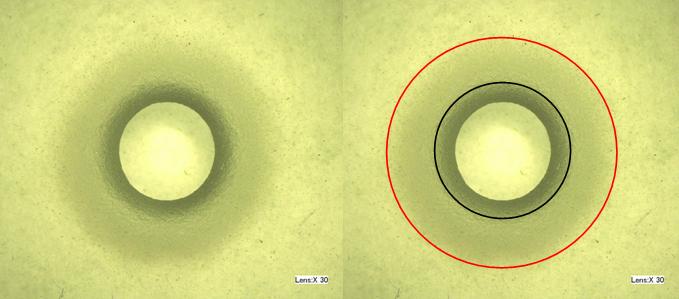

Before I dive further into the variables that impact this decision, let’s define “spot size.” Spot size is the affected region or the pattern that the blast stream erodes from a targeted surface. Simply put, the spot size is the etched or cut area surrounded by overspray. Overspray has no meaningful impact; rather, it is just a “frosting” on the surface.

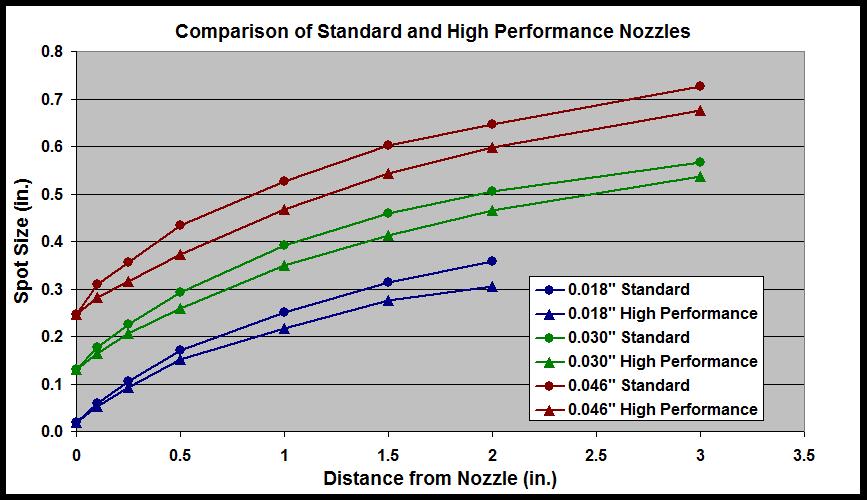

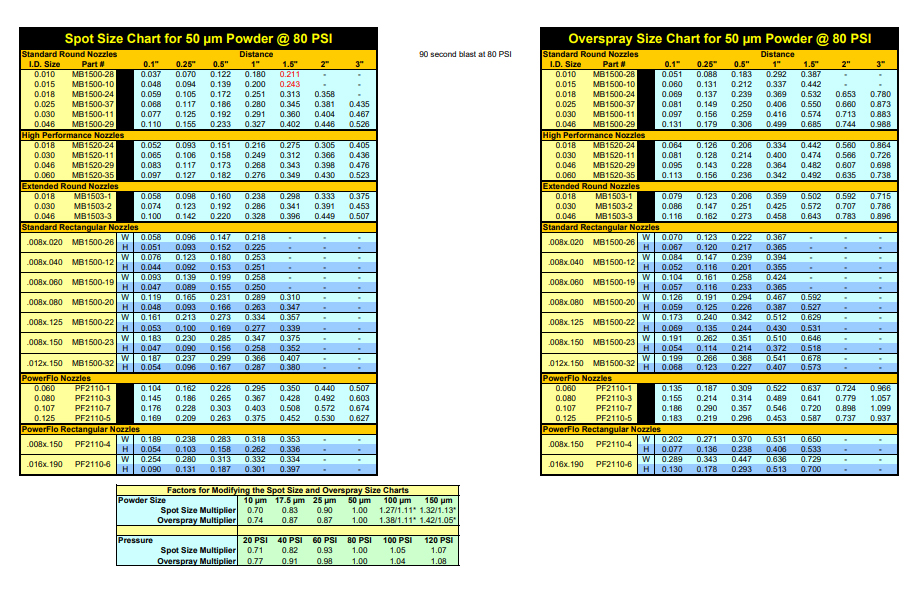

Spot Size Chart

Check out this reference chart that specifically matches spot size and nozzle distance.

The Nozzle is #1

The nozzle size, shape, and placement ultimately determine spot size, regardless of the media used or the velocity of the abrasive stream. Nozzle distance and spot size have a pretty simple relationship: the closer the nozzle is to the target, the smaller and sharper the spot size. The farther away the nozzle is held from the surface, the larger and less defined the spot size. You get the idea.

Nozzle Shape: Round vs. Rectangular

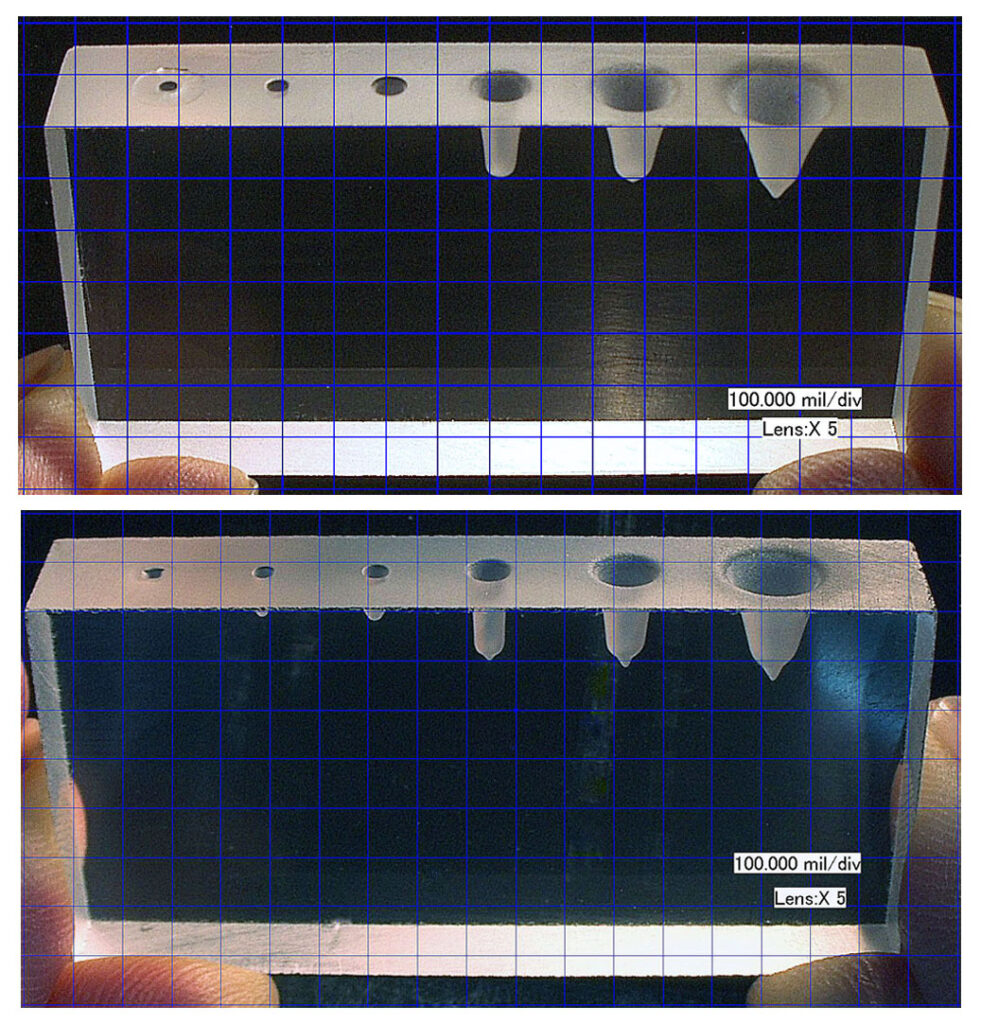

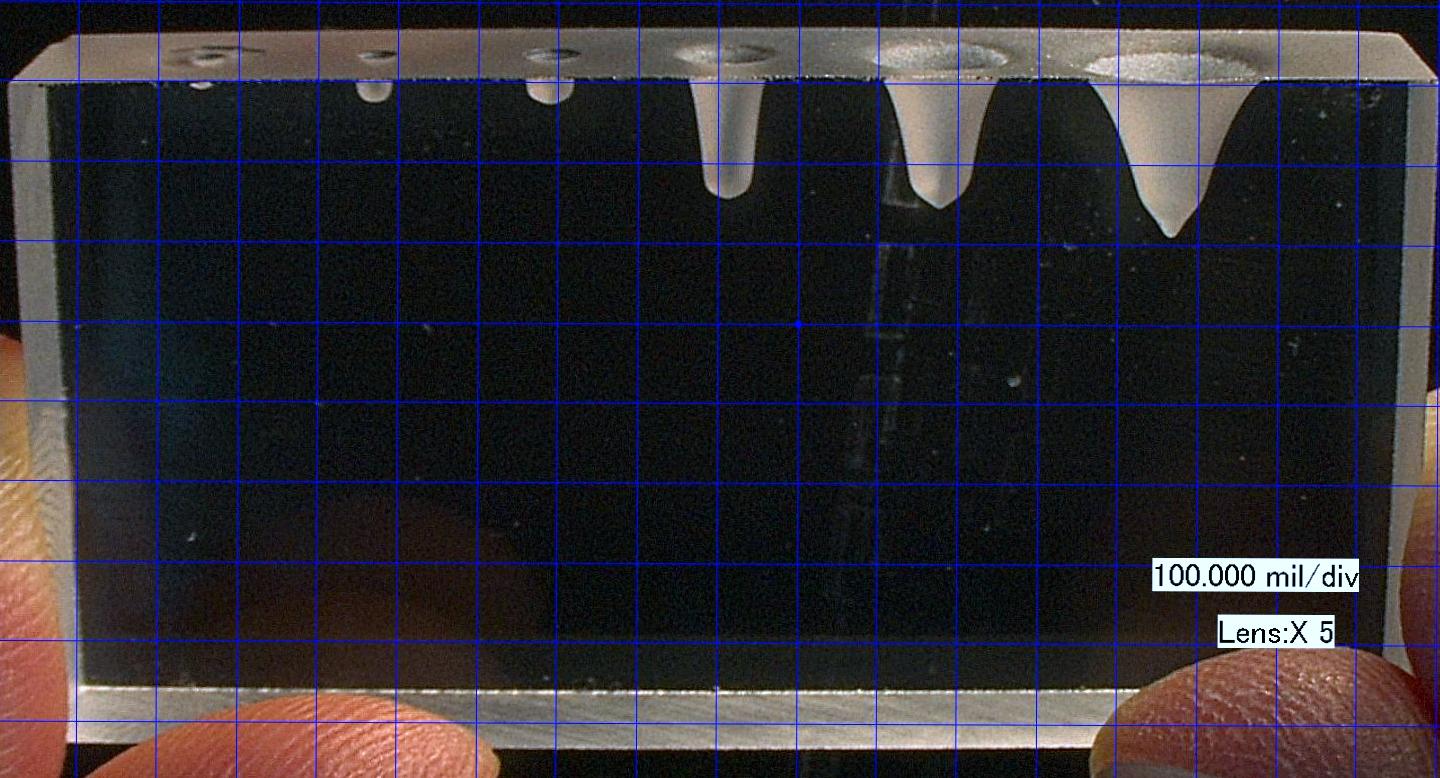

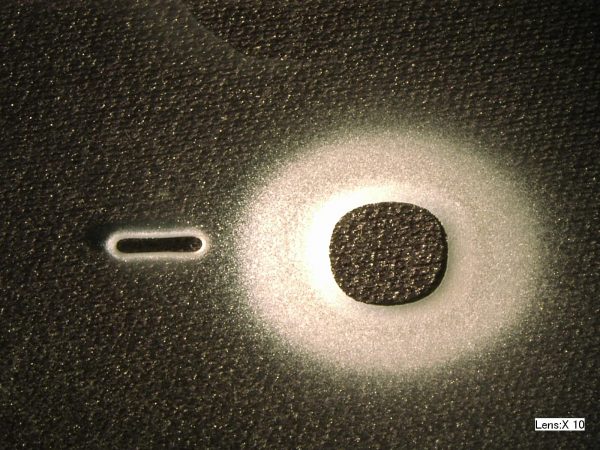

Nozzle shape has a trickier relationship with spot size. Round nozzles are the workhorse nozzles. They suit most applications, and the spot size from a round nozzle tends to remain circular at any distance. However, the spot size from rectangular nozzles gradually opens into a circular blast pattern as the nozzle pulls away from the target. Thus, rectangular nozzles are better for precise cuts at close distances (see image right).

How close is too close?

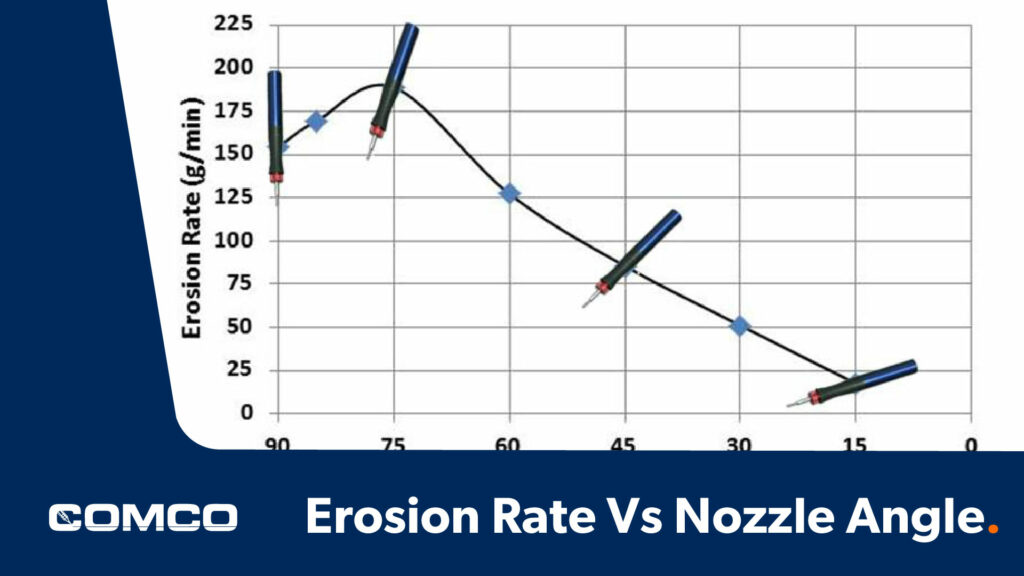

Abrasive particles ricochet between the nozzle and the part IF the nozzle is any closer than 0.025” to the target. Cut speeds dramatically decrease and overspray increases. Basically, holding the nozzle too close slows the jet stream and makes a mess.

Why Hold the Nozzle Farther Away?

Applications that require broad regions of texture or material removal benefit from greater nozzle distance. Abrasive particles spread over a wide area at this distance, reducing particle collision. Greater distance allows the use of a larger orifice, increasing abrasive density in the airstream, which results in faster part processing.

The jet tends to be most effective if the end of the nozzle tip is 1″-3″ from the targeted part. Abrasive particle velocity increases after it leaves the nozzle, reaching equilibrium with the air stream at about 1”, and begins to slow around 2″-3”.

Do Hi/Performance Nozzles Make a Difference?

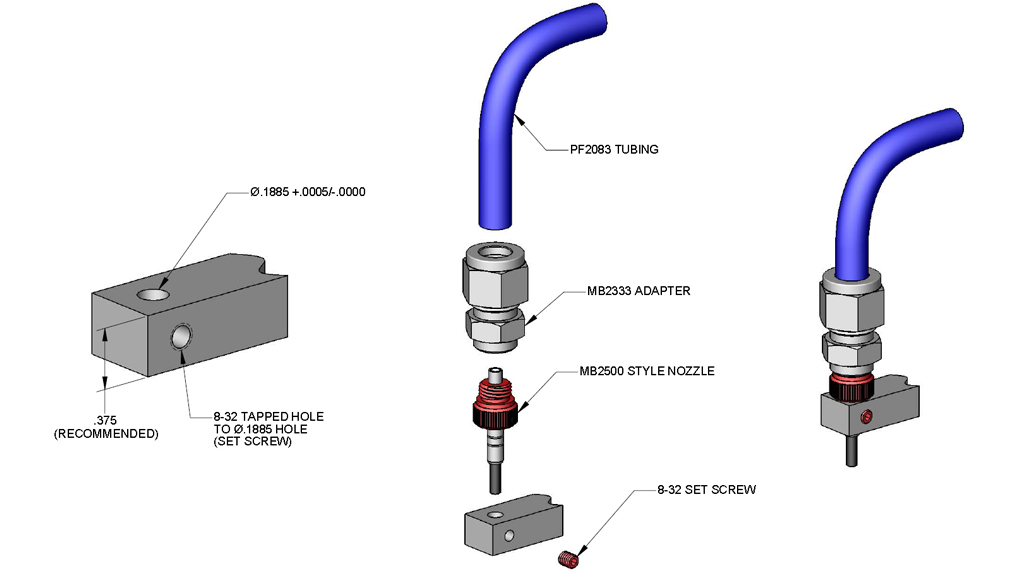

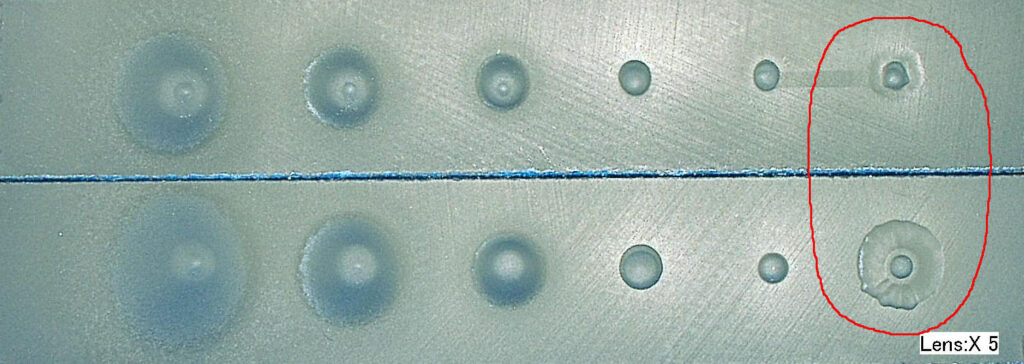

YES! The internal geometry of Comco’s Hi/Performance nozzle speeds up particle velocities by 30%, providing increased focus to the jet stream and reducing overspray. (Note the differences in bore depth and profile in the image below.) Increased focus allows an operator to reduce blast pressure and process parts faster. Plus, Hi/Performance nozzles have a lifespan 3-5x longer than a standard nozzle.