Case Studies

Turbine Blade Regeneration using microblasting

Goal: Clean Turbine Blades for Refurbishment

Whether you’re refurbishing land-based gas or jet-engine turbines, MicroBlasting is the ideal method of cleaning turbine blades. When turbines are split in two for maintenance, hot path components and combustion components are pulled out for repair. These parts take in and distribute cooling air within a turbine through multiple small holes, which can number more than 140 per component and be as small as 0.08 mm (.003″) in diameter. The holes are often present in airfoils and shrouds of many first- and second-stage components. Because of the complex geometry of these parts, MicroBlasting is ideal for cleaning coating and contaminants from them.

Why MicroBlasting?

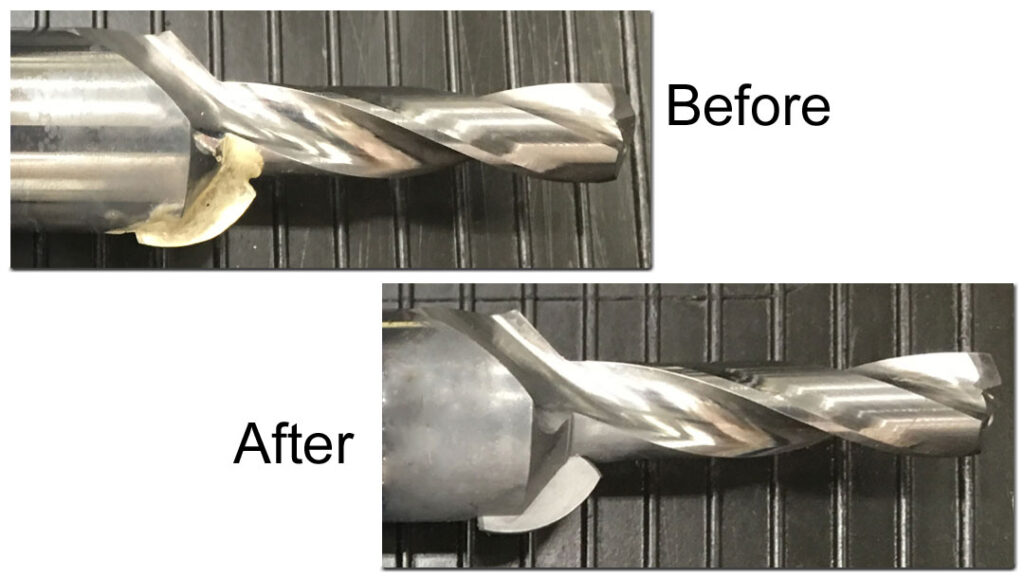

Removing the Protective layer

To avoid the need for multiple iterations of the cleaning process many turbine manufacturers have added in a MicroBlasting step. With the inclusion of this process in between the coarse grit blasting and chemical bath, the proper removal and surface finish can be achieved in 1-2 cycles. In addition to saving time, MicroBlasting also reduces abrasive consumption and chemical dependence.

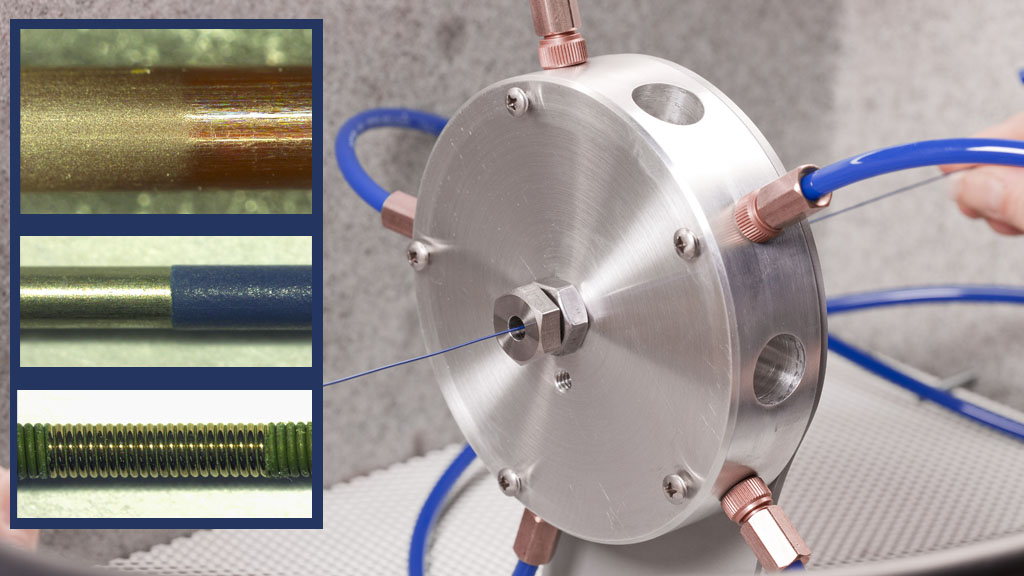

The precision nature of MicroBlasting means that it will not replace grit blasting for bulk removal of the coating. The pinpoint focus of the MicroBlasting abrasive stream is ideally suited for removing the coating from recessed and protected areas of the blade as well as inside the small air passages.

The precision in MicroBlasting comes from the small nozzles and fine abrasives that are used. With a uniform abrasive stream focused through a nozzle as small as 0.018”, the operator can easily target the coated areas and plugged air holes. The effective abrasive for this application is 25-50 micron aluminum oxide, with is a sharp cutting abrasive. For particulary difficult coatings silicon carbide, our most aggressive media, is required.

Chemical Processing

Adding MicroBlasting to the cleaning process may allow the chemical bath to be eliminated entirely. However, in some cases of thick coatings or extremely diffused materials, a chemical bath may still be required. Even in these cases there is a benefit to MicroBlasting. By cutting away at the top surface of the coating the chemical action is increased, “eating into” the blade surface more efficiently. As a result fewer dip cycles are required.

The Comco Difference

Sixty times per second, Comco’s patented modulator injects abrasive into the blaster’s air stream. The modulated mixing process is specifically designed to handle the 25 to 50-micron particles traveling through miniature nozzles. It keeps the abrasive stream uniform, cleaning air holes more effectively and avoids surges. Surging results in air passages becoming plugged rather than cleaned.

Applications Lab

MicroBlasting can be a huge time and resource saving asset to even the hardest to clean turbine blades. Want to know if MicroBlasting works for your application? Email us or give us a call at 1-818-841-5500.