Maintenance & Troubleshooting

Annual Maintenance Reminder 2023

It’s that time of the year again — time to check your supplies to get you through the end of the year. Do you have enough abrasive? Are your nozzles or window shield needing to be replaced?

It’s also a great time to perform some regular maintenance on your equipment. Check out the maintenance tips below to make sure your system is in excellent shape for the new year.

Taking Care of your AccuFlo

Keep your AccuFlo Running Smoothly:

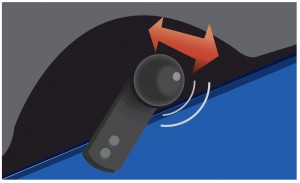

- Perform routine maintenance with the AccuFlo Tune-up Kit. This kit includes:

- PowderGate output fitting

- PowderGate nose piece

- Tank cover O-ring

- Avoid blasting mistakes Continue reading →

ProCenter Plus Upkeep

How often do you use the side mallets to shake off the excess debris from the HEPA filter? When was the last time you changed the filter?

Keep your ProCenter Plus clean by following these easy routine maintenance practices. Continue reading →

Keep your powder supply dry

Two common symptoms of moisture contamination are:

- Inconsistent flow: an initial stream of abrasive flows, but quickly tapers off.

- Clumping in the abrasive tank: clumps and clogs completely restrict abrasive flow out of the nozzle.

Ensure you start the new year right by following these steps on abrasive storage whether you’re closing for the day or a longer holiday break:

STORE POWDER PROPERLY

Always make sure containers (bags or bottles) remain tightly closed when not in use. Store powder in a cool, dry location avoiding wide variations in temperature to prevent the abrasive media from absorbing moisture from its surrounding environment.

CLEAR POWDER FROM THE TANK BEFORE LEAVING FOR THE DAY

The tank is NOT a sealed container, even with the machine off and depressurized. Leaving powder in the tank for a day or two can cause the powder to absorb enough moisture from the shop air to clump. Continue reading →