Manufacturers of MicroBlasting Equipment & Technologies

IF YOU ENGINEER CRITICAL AEROSPACE COMPONENTS, YOU CAN COUNT ON COMCO TECHNOLOGIES.

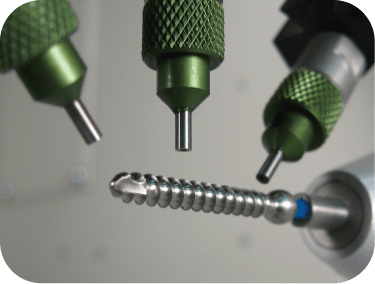

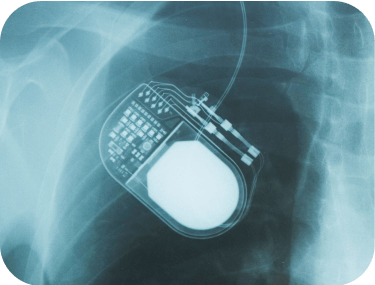

If you design life-saving medical implants, You can count on Comco systems.

IF YOU PROCESS SMALL, DELICATE, HIGH-VALUE PARTS, YOU CAN COUNT ON COMCO EQUIPMENT.

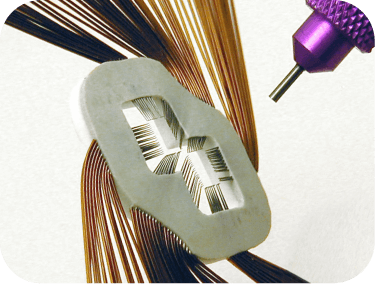

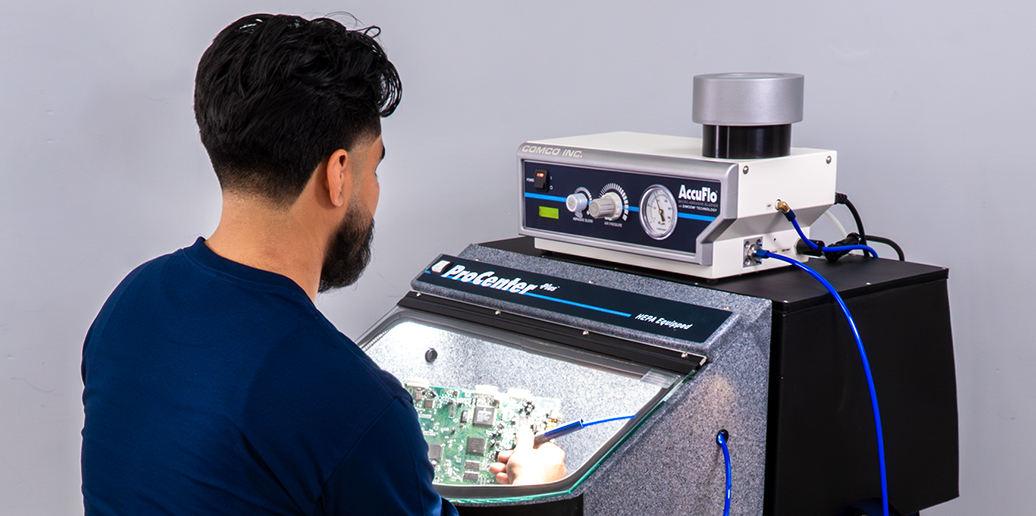

Comco’s Micro-Precision Sandblasting equipment, systems and solutions are proven to increase efficiency, enhance safety and optimize performance for a wide variety of partners across industries. What unique problem are you trying to solve?

***Meet us at MD&M West – Anaheim, CA -Feb 3-5, 2026 in booths #3409 and #4070***

Explore our Systems

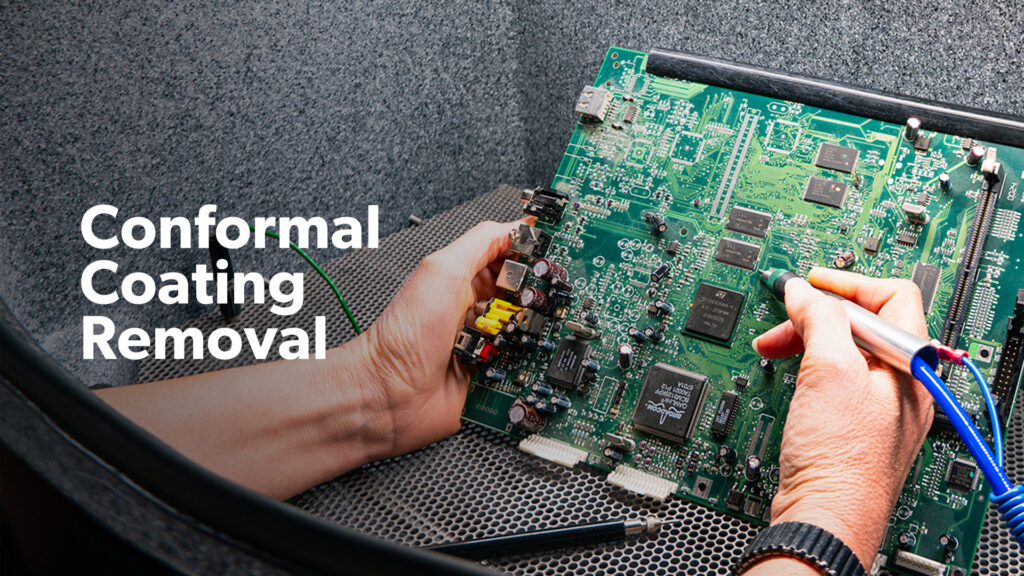

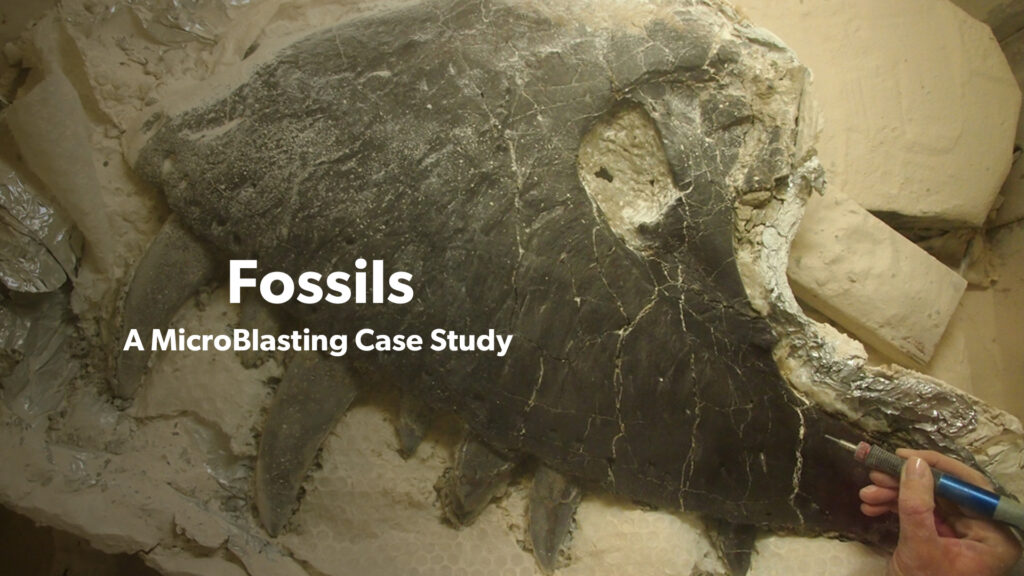

Our systems are used in a variety of industries to texture, deburr, clean, etch and cut a wide range of materials. Our customized solutions help businesses large and small meet today’s design, engineering, and manufacturing challenges.

Try our process

See what precision MicroBlasting can do for you. Send us a part and we’ll MicroBlast it, analyze it, and return it to you with a detailed report.

Schedule a demo