Equipment Updates

The JetCenter: the new Lathe on the Block

You Ask. We Build.

Every so often we get a customer request that stretches us beyond our current line of MicroBlasting systems, that sends our Engineering Team into the lab until they emerge victorious with a new design. Last year, we got such a request, and the result is the JetCenter.

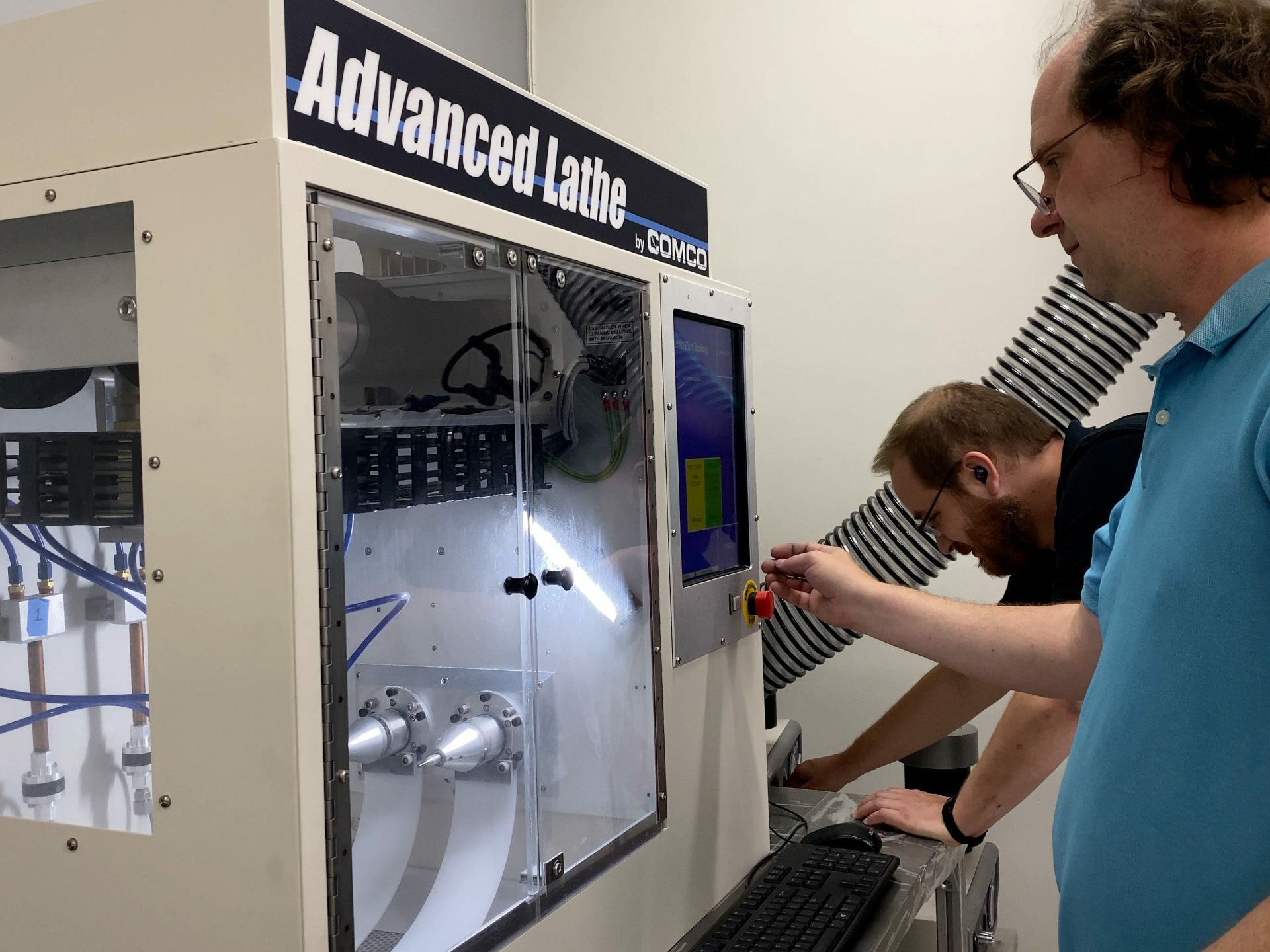

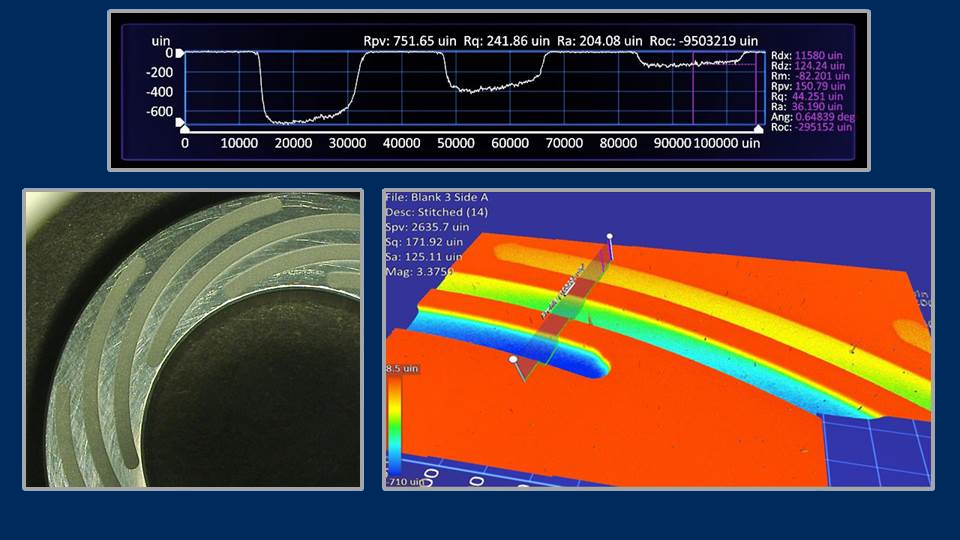

One of our existing customers needed to cut channels into a part and texture its surface. This part required a different geometrical approach than our existing automated system, the Advanced Lathe (LA3250), could provide. The customer’s part was similar in geometry and composition to a 300 mm wafer. The Advanced Lathe has excellent cylindrical capabilities, making it ideal for processing stents, texturing dental implants, lens engraving, and so on; but forcing a large, flat part into this existing platform proved impossible.

So, we developed a new system with more space and travel. The JetCenter is an expansion of our proven lathe platform, and it is ideal for large parts, trays of parts, and multiple part types.

Preface: Designing for Abrasive Environments

Designing for abrasive environments is tricky. Abrasive is both a helpful tool and an obstacle. The abrasives used in MicroBlasting can be as hard as diamonds and as fine as moondust.

Over 50 years of experience has forced us to develop a profound principle that you would never assume guides our Engineers. We shall now share this principle with you (drum roll, please!): keep sensitive machine parts away from fast-moving abrasive. (We blew your mind, right?)

How do we translate that principle into design? Equipment in the abrasive chamber of the JetCenter is designed to meet the IP67 rating, the highest industrial rating for dust resistance. We take extra precautions, including making sure:

- abrasive-resistant components are sealed, pressure purged.

- electronics are pressure-sealed in a separate chamber from the blasting area.

- downdraft airflow limits exposure of overhead slides.

- all nozzles are directed away from sensitive components.

Now, that we dealt with the nitty-gritty of abrasive, let’s look at what sets the JetCenter apart…

More Room for Travel

The overall envelope of the JetCenter is larger than our other automated systems, giving each axis more room to travel.

| Advanced Lathe | JetCenter | |

|---|---|---|

| X axis | 10.5" | 13" |

| Y axis | 5" | 13" |

| Z axis | 4" | 4" |

New Blast Head Designs

The Spin Wrist

The Spin Wrist spins a nozzle down into a bore. Primarily designed to hold right-angle nozzles, this blast head can perform unlimited revolutions without curling connected abrasive tubes.

The Twist Wrist

The Twist Wrist is the closest we have come in automation to creating the flexibility of a human wrist. While the targeted part is held vertically in a tooling fixture, the Twist Wrist twists around the center axis, following the circumference of a targeted part.

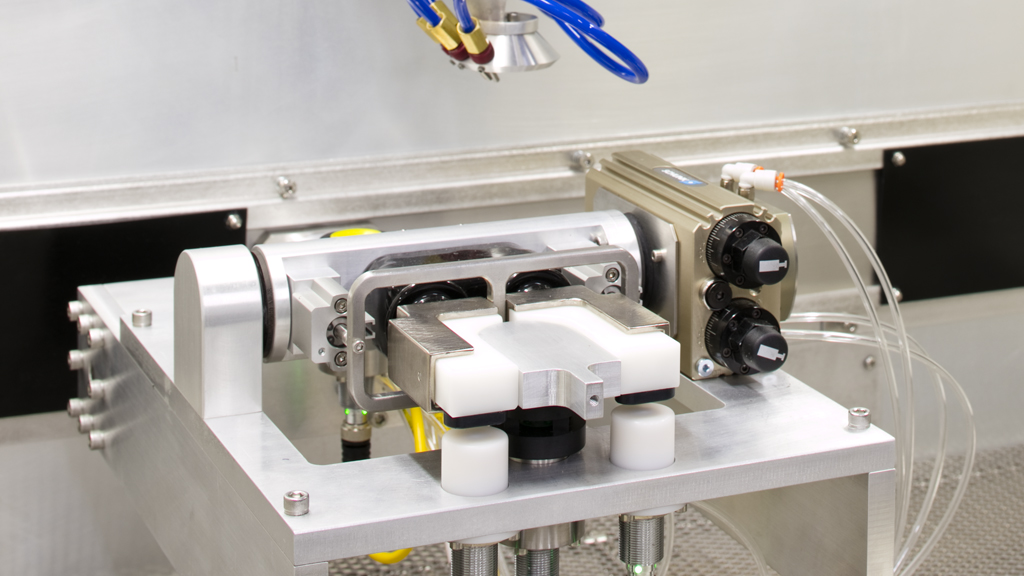

Take a look at the Twist Wrist and Gripper Flipper working together.

New Technology

The Flipper Gripper is an example of the type of sealed actuator technology we can add to the JetCenter. Unlike our main motion components which are stepper-motor controlled, we use actuators for simple motions located on the part tooling. The actuators are well-protected from abrasive.

Optional Automatic Door

Designing a door posed the greatest challenge. It needed to be automated, move smoothly and seal well. We decided to avoid the barn-door design featured on some Advanced Lathes. Instead, we added an upward-sliding door that is either counterbalanced or actuated by air cylinders. This externally controlled option enables robotic loading and unloading in high-volume applications. We think it is quite nice.

Improved Abrasive Quick Disconnect

It’s the little upgrades that mean so much. We replaced the abrasive disconnect hand lever with a pneumatic quick disconnect to improve blast head interchangeability.

This AQD simplifies swapping blast heads or abrasive lines for different applications. Depending on the process, up to 4 micro-precision sandblasters can be connected to the JetCenter at one time.

Intuitive User Interface

This User Interface is easy to operate. Take a look: