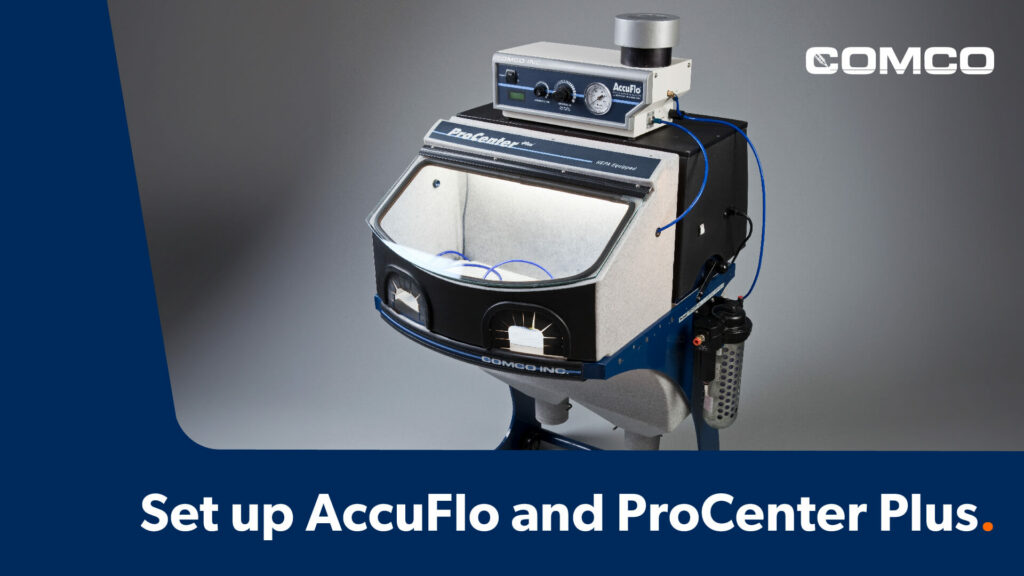

ProCenter Plus

The ultimate manual workstation

Designed specifically for MicroBlasting, ProCenter Plus combines a compact dust collector and chair-height work chamber in one freestanding unit, creating a clean, comfortable work environment with great visibility.

Convenient for any workspace

The perfect companion to AccuFlo, ProCenter Plus combines all necessary accessories into one self-contained system on wheels. The unit rolls easily through any standard doorway and has a footprint of only 30″ x 34″ so you can blast wherever the work is.

Key features

-

Even quieter

Our engineers designed the latest ProCenter Plus to reduce noise without sacrificing efficiency. This compact system not only does a better job of collecting spent abrasive, it does so more quietly, operating at a sound level of just 68 dBA.

-

Even cleaner

ProCenter Plus comes equipped with an easy-to-replace HEPA filter. Spent abrasive is swiftly evacuated from the chamber, keeping the work area clean. HEPA air filtration means 99.97% of all particles greater than 0.3 micron in size are removed.

-

Easy to maintain

Spent abrasive is quickly evacuated from the blast chamber and captured in the media hopper. Disposal is simplified with 2 large butterfly valves.

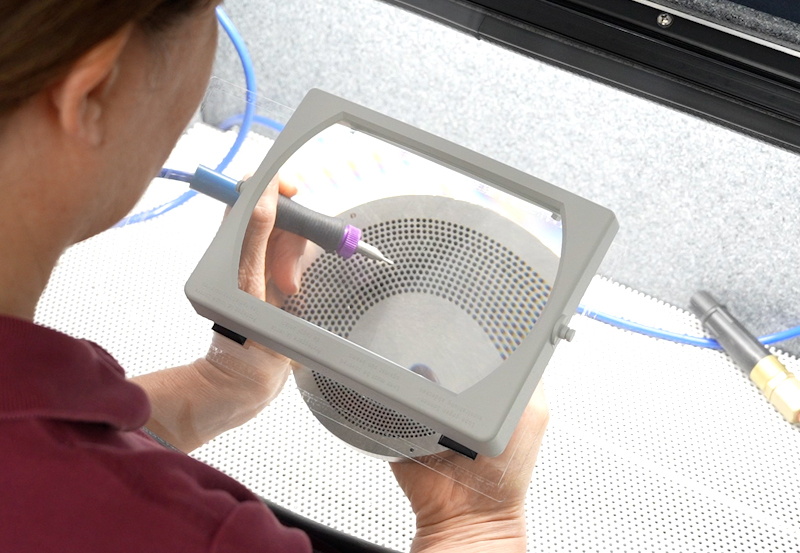

Magnifier

The Magnifier boosts visibility without impairing the ergonomic design of your workstation.

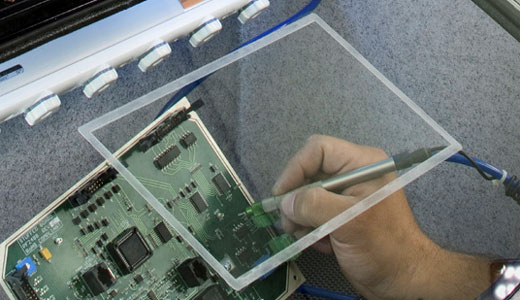

Window Shields

Protect Your Investment Comco’s VisionPlus Window Shields extend the life of your workstation’s viewing window by protecting the inside of the glass from damage caused by abrasive ricochet.

Models:

CTR200 Standard Unit

CTR201 with ESD control feature

Available in:

115V / 60Hz / 290W or 230V / 50Hz / 290W

115V / 60Hz / 290W or 230V / 50Hz / 290W

Size:

30″ wide x 46″ high x 34″ deep

30″ wide x 46″ high x 34″ deep

Interior Space:

2.2 cubic feet 24″ wide x 14″ deep x 10″ (approx.)

2.2 cubic feet 24″ wide x 14″ deep x 10″ (approx.)

Window:

Tempered glass opening (hinged) 23″ x 11″

Tempered glass opening (hinged) 23″ x 11″

Weight:

162 lbs / 73.5 kg

162 lbs / 73.5 kg

Lighting:

40W cool fluorescent lamp

40W cool fluorescent lamp

Air Flow:

500 SCFM

500 SCFM

Filter:

HEPA- 99.97% efficiency on 0.3 micron-sized particles

HEPA- 99.97% efficiency on 0.3 micron-sized particles

Filter area:

30 ft²

30 ft²

Inlet Air Pressure::

80 psi air supply of 4 SCFM required in addition to normal blaster supply

80 psi air supply of 10 SCFM required for CTR201 models (ESD control) in addition to normal blaster supply

Sound level:

68 dBA

68 dBA

Compatibility:

Works with all models of Comco micro-abrasive blasters

Works with all models of Comco micro-abrasive blasters

Try our process

See what precision MicroBlasting can do for you. Send us a part and we’ll MicroBlast it, analyze it, and return it to you with a detailed report.

Schedule a demo