Process Optimization

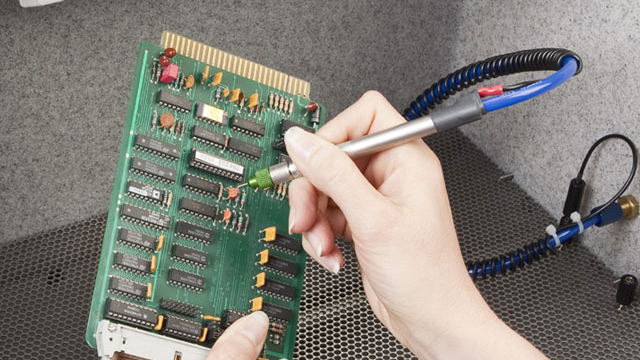

Removing a Ductile Layer from a Brittle Substrate

The selective cleaning process uses the abrasive qualities of MicroBlasting to carefully erode layers of unwanted material from a base substrate. The process takes advantage of the different physical properties of the two layers. Brittle materials can be removed from soft ductile layers, or soft ductile layers can be removed from brittle layers.

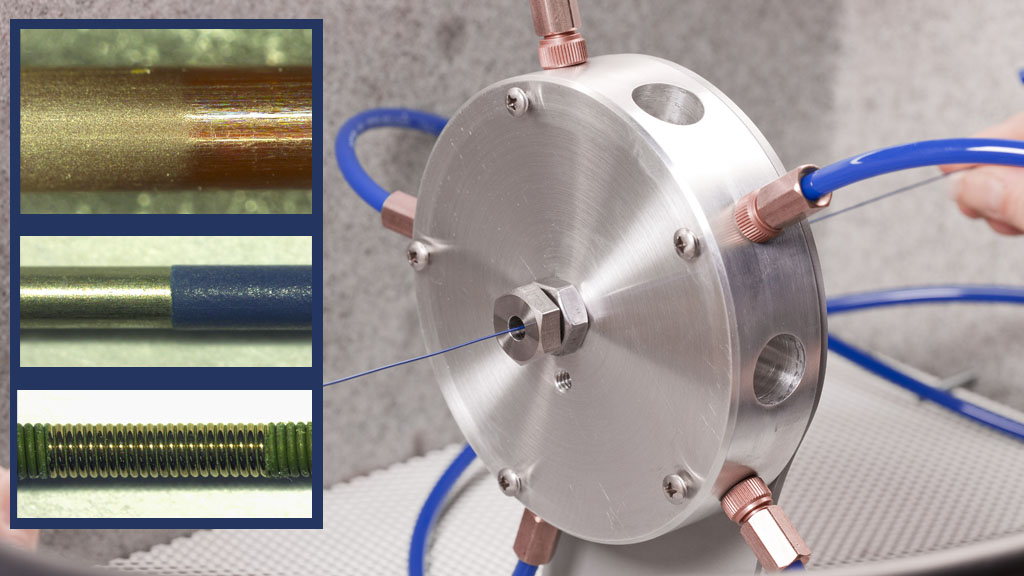

Two blasting variables to consider before removing a soft ductile material from a brittle base substrate are abrasive selection and particle velocity.

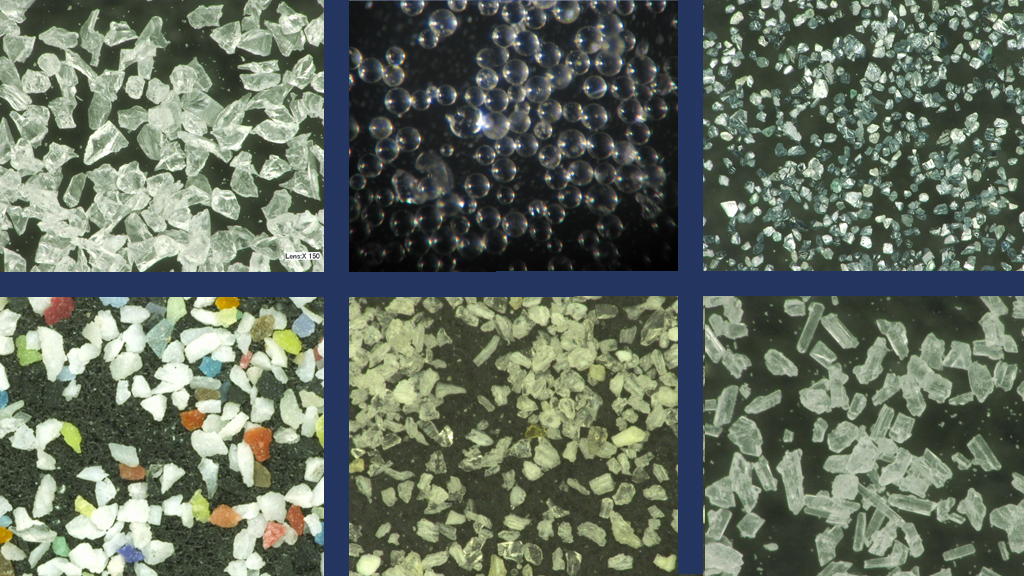

Abrasive Selection

This application usually involves a soft polymer or coating layers over a ceramic wafer, metal structure, or circuit board. The goal is to make sure that the abrasive selectively attacks the top ductile layer without causing damage to the brittle layer underneath. to do so, the abrasive media should be hard enough to cut through the ductile layer but not as hard as the brittle material underneath. Common abrasives used in these applications are sodium bicarbonate, wheat starch, walnut shell, and plastic media.

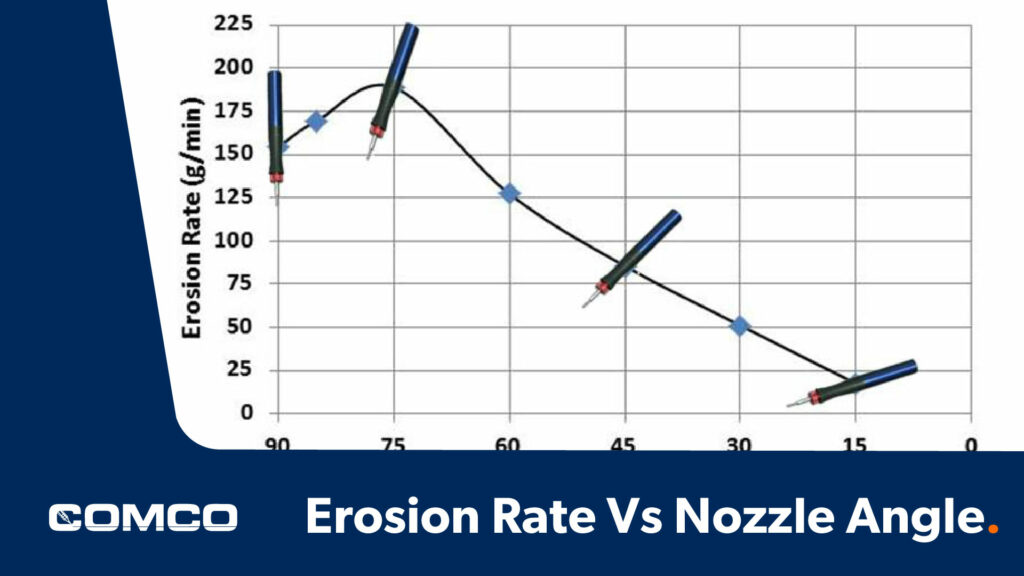

Particle Velocity

The typical range of pressure for selective cleaning of ductile layers from a brittle substrate is 40-80 psi. High particle velocities can cause the abrasive stream to impact and damage the substrate if the abrasive and the substrate are close in hardness or if the abrasive media contains foreign contaminants.

Caution! The tendency is to use higher velocities because the process can go quicker that way. However, if not done carefully a higher velocity stream can damage the brittle substrate.

Applications Lab

We’ll work closely with you by applying our engineering skills to your problem, providing the process with our technologies, and sharing our accumulated expertise to develop solutions that are efficient and cost effective.